All Activity

- Past hour

-

Tikett joined the community

- Today

-

Gian_ joined the community

-

Hi all, I've been trying to upload a fuselage i designed on blender but the file object dosn't render on planemaker, I've used the addons to convert the objet directly in blender but the problem persist. Any suggestions? Thanks for the help fusoliera5.obj

-

Hi I had this problem too. It has to be some window that opens during flight. In my case was Xchecklist that is probably not yet compatible with XP12.4....good luck!

-

When you pack light for an overnight trek, practical choices matter and the Bluefire 230g Screw Top Gas Canister often shows up on experienced kit lists. It sits at an intersection of portability and usable fuel that many outdoor cooks and small group campers appreciate. Recent consumer interest in outdoor pursuits and practical preparedness has nudged more people to rethink gear that actually performs when conditions are uncertain. That makes a canister that balances how much it holds with how easy it is to carry a relevant conversation starter. The appeal begins with everyday usability. A canister in this size class gives enough fuel for multiple meals without forcing a heavy carry burden, and its threaded cap design makes attachment and storage straightforward for people who use compact stoves. For someone who values calm, predictable equipment behavior, the predictability of a screw top connection can be reassuring. It also reduces fiddly moments when the weather is breezy or when campsite lighting is low. Practical features like this translate into small time savings that add up across a weekend outing. Quality and manufacturing practice are another part of the equation readers care about. Buyers paying attention to supply chain stories and product safety reports have been more selective about where their gear comes from. A company that provides clear product information and visible production controls helps people make choices without guesswork. That clarity matters not only for recreational use but also for small businesses that package outdoor kits for customers or events, since predictable performance supports consistent experiences. Beyond the single user, there is an environmental angle to consider. Conversations around sustainability and waste reduction have nudged many outdoor enthusiasts toward strategies that limit disposable packaging and unnecessary replacements. Choosing a fuel container that minimizes the ratio of packaging to usable resource can reduce trips to stores and the number of spent canisters left behind. The design and lifecycle of a canister therefore play into broader consumer values around responsible outdoor recreation while still delivering the simple goal of cooking a meal. Compatibility is another practical point. Many people are switching between different portable stoves and burners as they test gear or host small outdoor gatherings. A threaded screw top style is compatible with a wide range of stoves designed for that interface, which reduces the need to carry adapters or extra equipment. For anyone who travels with a stove that follows common connection designs, this translates into fewer surprises during setup and a smoother user experience. In the context of recent headlines that touch on fuel availability and travel habits, the choice of a reliable, easy to handle fuel container can feel more relevant. When travel and outdoor plans change quickly, having a compact source of heat and cooking capability that stores easily and is simple to use becomes part of smart packing. This is not about dramatic claims but about aligning a small, everyday item with how people actually move through their plans. Practical tips for using this style of canister emphasize safe handling and sensible storage. Keep spare canisters in a cool, shaded place away from direct heat sources, and check seals before transport. When setting up a stove, place the canister on a stable surface and avoid overexerting the connection. Treat fuel containers as tools that deserve routine checks, which helps avoid common hassles and supports a relaxed outdoor rhythm. For those who provide group catering or teach outdoor skills, this size class offers predictable burn characteristics that help with planning for multiple portions. It lends itself to menus that include boiling, simmering, and reheating without forcing multiple fuel swaps in the middle of a session. That logistical ease can make the difference between a smooth lesson and a rushed one when time is limited. When evaluating purchases, look for suppliers that present clear product details and are open about their manufacturing practices. Clear labeling and accessible support channels help buyers feel confident in choices that will be taken into remote places or used in public programming. Transparency in production and packaging shows respect for the customer and for the environments where the product will be used. If you are comparing options, allow practical experience to guide your decision. Think about how you carry gear, the kinds of meals you prepare, and whether a threaded connection fits the stoves you already own. Small, thoughtful choices in gear can reduce weight and friction in the field, making it easier to enjoy the activity itself rather than troubleshooting equipment. For those who want to explore product specifics and sourcing, the manufacturer offers a product page with images and supply options that reflect their production approach. A direct look at the source can help confirm whether the style aligns with your stove interface and packing habits. https://www.bluefirecans.com/ .

-

Fabrication shops face mounting pressure to improve productivity while maintaining quality standards in aluminum welding operations. Aluminum Welding Wire ER4943 represents a newer approach to filler metal formulation that contrasts with conventional options that have dominated the industry for generations. Examining these differences reveals how material selection impacts everything from weld integrity to production efficiency. Traditional filler wire selections have evolved around specific use cases, with each designation addressing particular base material families or joining scenarios. High silicon content wires became standards for their ability to create fluid weld pools and resist cracking when joining casting alloys. Pure aluminum options served applications requiring maximum ductility and corrosion resistance. Magnesium bearing fillers provided strength when welding structural alloys. These established choices continue to serve countless applications effectively. The challenge arises when fabricators encounter situations that fall between these traditional categories. Assemblies combining heat treatable and non heat treatable alloys present difficulties for conventional filler metals, which may excel with one base material type while underperforming with the other. Mixed material welding has become increasingly common as designers seek to optimize component performance by placing different alloys where their specific properties provide advantages. Newer filler formulations take a different philosophical approach by attempting to perform adequately across broader application ranges rather than excelling in narrow niches. This versatility comes from balanced chemistry that incorporates moderate amounts of multiple alloying elements instead of relying heavily on a single element. The result is a compromise that sacrifices some specialized performance to gain flexibility across diverse welding scenarios. Crack sensitivity represents a crucial comparison point between filler options. Traditional high silicon wires reduce hot cracking through their effect on solidification behavior, creating a composition range that remains partially liquid during cooling. This extended freezing range allows the weld to accommodate thermal stresses without fracturing. Alternative formulations manage cracking through different mechanisms, balancing silicon content with other elements that modify grain structure and reduce strain concentration. Anodizing response matters greatly in architectural and consumer product applications where appearance drives purchasing decisions. Conventional filler metals sometimes produce color mismatches after anodizing treatment, creating visible weld lines that require additional finishing work or cosmetic covers. Different filler chemistries aim to minimize these color variations by creating weld metal that responds similarly to surrounding base material during the electrochemical anodizing process. Feedability through welding equipment affects operator experience and production uptime. Wire surface quality, cast and helix characteristics, and dimensional consistency all influence how smoothly filler metal feeds from spools through liners to the welding arc. Manufacturers of any filler wire must ensure their products meet mechanical handling requirements regardless of chemistry, though some compositions present greater manufacturing challenges than others in maintaining tight tolerances. Porosity formation threatens weld quality across all aluminum filler types, as hydrogen contamination creates gas pockets during solidification. Traditional wires have established track records for porosity resistance based on decades of field use under various conditions. Newer formulations must demonstrate comparable resistance while potentially offering other performance benefits. The interaction between filler chemistry and hydrogen solubility remains complex, influenced by factors beyond simple compositional analysis. Joint strength requirements drive many filler metal decisions, particularly in structural applications where welds must carry significant loads. Conventional options typically require matching filler strength to the weaker base material in a joint, accepting underutilization of stronger materials. Aluminum Welding Wire ER4943 and similar alternatives sometimes provide improved strength matching across dissimilar material combinations, though actual performance depends on specific base metals involved and dilution effects during welding. Weldability encompasses more than just the ability to create a joint; it includes considerations of parameter sensitivity, position capability, and tolerance for contamination. Traditional fillers benefit from extensive documentation of acceptable welding parameters developed through widespread use. Alternative options require welders to develop familiarity with how these materials behave across different process variables, though fundamental aluminum welding principles still apply. Inventory management becomes simpler when fewer filler metal types can address more applications. Shops working with multiple aluminum alloy families traditionally stock several different filler wires to ensure appropriate matches for various base materials. A more versatile filler that performs adequately across broader ranges potentially reduces inventory complexity, though fabricators must verify that general purpose performance meets their specific quality requirements. Cost considerations extend beyond filler metal purchase price to include factors like reduced inventory carrying costs, fewer changeovers between different wire types, and potentially simplified procedure qualification requirements. However, if a specialized traditional filler outperforms a versatile alternative in a high volume application, the production advantages may outweigh any inventory simplification benefits. The comparison between traditional and alternative filler metals ultimately requires evaluating specific fabrication needs against material capabilities. Neither approach universally surpasses the other, and informed selection depends on understanding the strengths and limitations each brings to particular welding scenarios. Both categories continue to evolve as manufacturers refine formulations and processing methods. Fabricators seeking guidance on filler metal selection benefit from suppliers who maintain expertise across multiple product families and understand how different options perform in real world applications. Technical support that goes beyond basic product specifications helps translate material properties into fabrication outcomes. For comprehensive information on filler metal options including Aluminum Welding Wire ER4943 and traditional alternatives, https://kunliwelding.psce.pw/8hpj2n provides resources that connect material science with practical welding knowledge.

-

Winter mornings transform simple commutes into tests of preparation and comfort. Cold air seeps into vehicles overnight, chilling every surface and making those initial minutes behind the wheel particularly unpleasant. An Aijun Thermos Car Mug filled with hot coffee or tea becomes more than a beverage container during these frigid months—it represents sustained warmth that counters dropping temperatures both inside and outside your body. Understanding why stainless steel construction maintains heat so effectively during winter drives reveals the science behind this daily comfort. Heat transfer occurs through three primary mechanisms: conduction, convection, and radiation. Standard mugs allow all three processes to steal warmth from beverages rapidly. Conduction moves heat through container walls into cold air. Convection currents carry warmth away as heated air rises from liquid surfaces. Radiation releases thermal energy invisibly into surrounding space. Winter conditions accelerate these losses, with frigid cabin temperatures creating steep thermal gradients that drain heat aggressively. Double wall construction provides the fundamental defense against heat loss. Two layers of stainless steel create a barrier where a gap separates inner and outer walls. This space interrupts direct conduction pathways that would otherwise allow heat to flow rapidly from hot liquid through container walls into cold air. The separation distance matters less than the interruption itself, as even small gaps dramatically reduce heat transfer compared to single wall designs. Vacuum sealing between walls elevates temperature retention dramatically. Removing air molecules from the gap eliminates convection entirely, as gases conduct heat through molecular collisions. Without air present, no collisions occur, preventing heat transfer through this mechanism. The vacuum also minimizes conduction, as the few remaining molecules cannot effectively transport thermal energy across the gap. This creates near-total insulation that maintains beverage temperatures for hours. Reflective interior surfaces combat radiation heat loss. Polished stainless steel reflects infrared radiation back toward the liquid rather than allowing it to escape through container walls. This mirror effect traps radiant heat inside, adding another layer of insulation beyond physical barriers. The combination of vacuum insulation and reflective surfaces addresses all major heat loss pathways simultaneously, creating remarkably effective temperature retention. Lid design influences overall performance as significantly as wall construction. Heat escapes readily through openings, making lid quality critical for maintaining temperatures. Threaded closures with rubber gaskets seal tightly, preventing warm air from escaping and cold air from entering. Drinking mechanisms should minimize opening size and duration, as each sip allows brief heat exchange with surrounding air. Slide closures and push-button openings limit exposure compared to fully removable lids. Material thickness affects both insulation and durability. Thicker stainless steel provides greater structural strength, resisting dents that compromise vacuum integrity. However, excessive thickness adds weight without proportionally improving insulation, as the vacuum gap provides primary temperature retention. Manufacturers balance these factors, selecting gauges that deliver durability while maintaining reasonable weight for daily handling. External temperature extremes test insulation effectiveness. Winter conditions create harsh environments where ambient temperatures fall far below comfortable levels. The greater the temperature difference between beverage and surroundings, the faster heat loss occurs without adequate insulation. Quality vacuum-insulated containers maintain performance across wide temperature ranges, preventing excessive heat loss even during severely cold weather. Preheating containers enhances temperature retention through thermal mass management. Rinsing mugs with hot water before filling warms the stainless steel, reducing the initial thermal load when adding beverages. Cold metal absorbs heat from liquids immediately upon contact, lowering starting temperatures. Preheated containers begin at higher temperatures, providing longer duration before drinks cool to unacceptable levels. Fill volume impacts temperature maintenance duration. Larger liquid volumes possess greater thermal mass, retaining heat longer than small amounts. A fully filled container maintains temperature more effectively than one quarter full, as the liquid-to-surface-area ratio favors heat retention. However, practical considerations like drinking throughout commutes mean containers rarely stay full, so insulation quality matters more than maximizing fill levels. Handle and grip design considerations affect user experience during cold weather. Bare metal handles conduct cold from exterior surfaces, creating uncomfortable grips. Insulated or plastic handles prevent this issue, though they may feel less durable. Some designs eliminate handles entirely, relying on rubberized exterior coatings for grip. Each approach presents tradeoffs between comfort, durability, and aesthetic preferences. Cleaning maintenance affects long-term insulation performance. Accumulated residues inside containers reduce surface reflectivity, diminishing radiation heat retention. Regular thorough cleaning preserves maximum performance. Additionally, damaged gaskets or loosened lids compromise seals that prevent heat escape. Periodic inspection and replacement of worn components maintains original insulation effectiveness. Base materials prevent heat loss through container bottoms. Some designs incorporate insulated bases similar to wall construction, while others use solid construction that conducts heat to surfaces. During winter drives, this detail matters less than wall insulation, as cup holders provide minimal thermal mass compared to surrounding air. However, comprehensive insulation delivers marginally better overall performance. A Thermos Car Mug engineered with proper vacuum insulation and thoughtful design details transforms winter commuting experiences. Morning coffee remains hot through long drives, providing consistent comfort regardless of outside temperatures. The science behind stainless steel thermal retention explains why these containers outperform alternatives so dramatically during cold weather. Winter driving demands reliable equipment that performs consistently despite challenging conditions. Your Thermos Car Mug delivers sustained beverage temperatures that enhance comfort and safety by reducing distraction from temperature disappointment. Quality insulation technology makes cold weather commutes more bearable through simple reliable heat retention. Those seeking dependable thermal containers engineered specifically for automotive use can examine various designs balancing insulation performance with practical features. Visit https://www.aijunware.com/product/ to compare options suited to winter driving conditions and personal beverage preferences.

-

lanyan2012 joined the community

-

No LOC and GS when on ILS APP on IXEG B733

Litjan replied to rafaromanosp's topic in General Discussion

This is strange - does this only happen at one airport or at several? There is always the possibility that other plugins interfere (fly with lua, etc.) if you could attach the log.txt file from a run where the ILS did not work, I could take a look. Also, try to post a screenshot that shows the Mode Control Panel (where you set the ILS course) and the VHF NAV radios (where you set the ILS frequency). -

Yariv joined the community

-

G, have you received any responses? i am too waiting for this Ovation to be available for X-Plane 12 and fly a C-172 in the meantime:-)

-

You’ll need to downgrade.

- Yesterday

-

ca177 started following Challenger 650 CTD X-Plane 12.4.0-b2

-

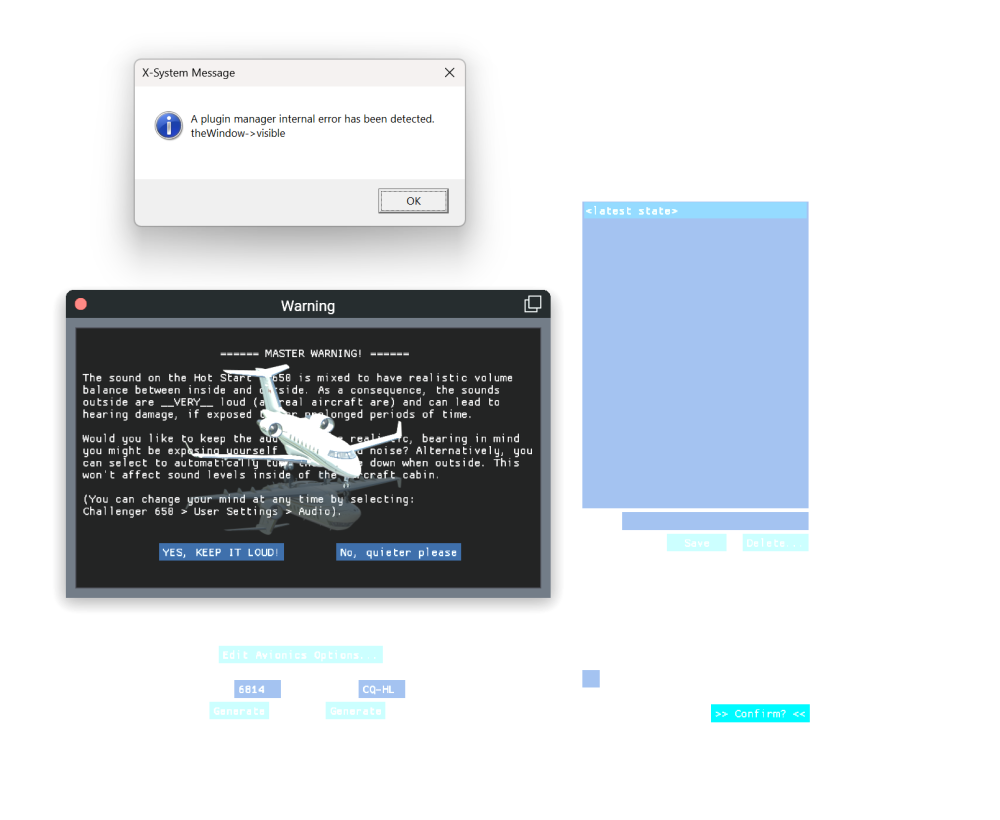

Hi All, I have a fresh copy of the Challenger 650 in X-Plane 12.4.0-b2 that will crash to desktop immediately after clicking enter FBO and confirm. A pop up indicating "A plugin manager internal error has been detected. theWindow ->visible" shows up. I do not have the DataRefTool installed. Log file is also attached. Please let me know how to get around this. Thank you, Zicheng Log.txt

-

Patrick_TA joined the community

-

That's expected, yes. Indeed.

- 1 reply

-

- 1

-

-

diamonddriller started following CTD with X-Plane 12.4

-

Me too. I was just getting my log.txt, but suddenly thought to look here

-

alstr started following Screen brightness

-

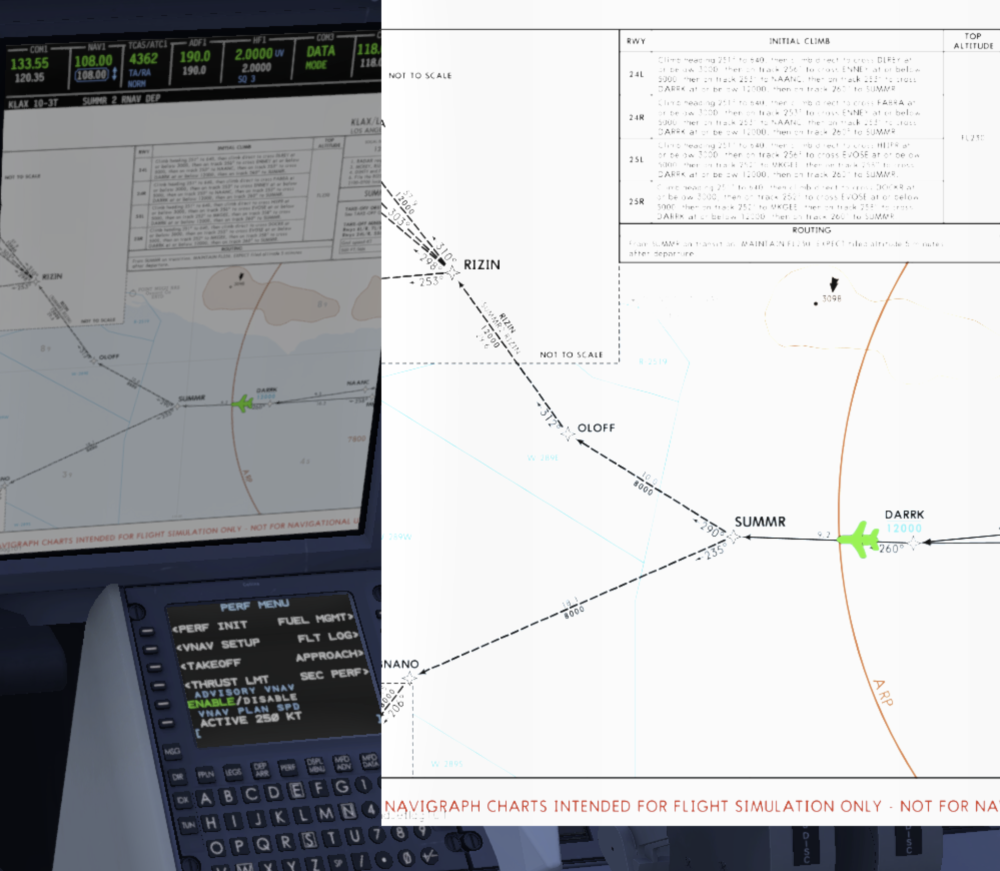

Is there meant to be a discrepancy between the brightness of the cockpit screens and the pop-out ones? It makes reading difficult without excessively fiddling around with brightness controls. (And of course this screenshot shows the now regular issue of the hydraulic summary having gone crazy). Maps in particular are very difficult to read at times. I find brightness of displays/lighting quite a challenge to manage in general compared to other aircraft. The overhead panel lights on bright look like the aurora borealis. I'm sure some of this is X-Plane.

- 1 reply

-

- 1

-

-

general_a9 joined the community

-

I thought I tried that and it didn't work, but I'll see next time.

-

No LOC and GS when on ILS APP on IXEG B733

rafaromanosp replied to rafaromanosp's topic in General Discussion

Hello, after performing a clean installation the aircraft works correctly on the first run. However, once I close and reopen the simulator the issue returns. I’ve checked the random failures settings and none are active. Ive tested other aircraft and they work as intended. -

vShannon joined the community

-

belocaugusto joined the community

-

Hi Patrick, just reading this - I am happy that you got it solved - and thanks for reporting back with the solution! Happy flying!

-

Cara Menghubungi Customer Service AirAsia , Hubungi di nomor 0814-1355.5.472. Atau melalui nomor WhatsApp/CS: +62814)13-555472. Jelaskan Masalahnya Terkait Penerbangan Anda, Layanan Bantuan 24/7. Live MOVE...siap

-

Cara Menghubungi Customer Service AirAsia , Hubungi di nomor 0814-1355.5.472. Atau melalui nomor WhatsApp/CS: +62814)13-555472. Jelaskan Masalahnya Terkait Penerbangan Anda, Layanan Bantuan 24/7. Live MOVE...

-

Bagaimana Cara Menghubungi CALL CENTER AirAsia? -

hitmen82 replied to hitmen82's topic in Screenshots

Untuk saluran resmi silahkan menghubungi Customer Service AirAsia (08141355547.2) Untuk Whatsapp +62 8141355.5.47.2) siap -

Untuk saluran resmi silahkan menghubungi AirAsia Customer Service (08141355547.2) Untuk Whatsapp +62 8141355.5.47.2)

-

Pengingat Penting Layanan Contact center resmi AirAsia hanya...

hitmen82 replied to hitmen82's topic in Communal Links

Contact Center:+62 8I4I3555472 AirAsia (WhatsApp Text) -

jimvanzino started following X-Aviation Installer Fails on Windows for LEC DC-3 V2

-

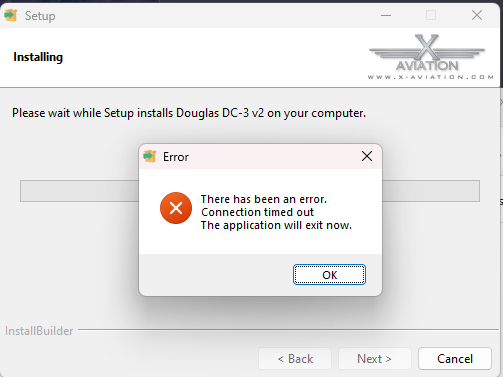

**Solved* Not sure what changed but I just kept running the installer over and over and it finally completed the install! Hello Everyone, I am new to this forum but have been flying X-Plane since the original release way back on DVD's.. I purchased the LEC DC-3 V2 today but cannot get the X-Aviation installer to complete and am looking for some help. I've put in a support ticket on X-Aviation as well but thought I would ask the community if anyone else is having an issue. I have tried several times now but the installer for the LEC DC-3 will not complete on my system. I have tired re-downloading the installer, turning off any third-party programs running (Razor App), turning off all of my firewall stuff in Windows Defender, and using a different directory for the download. I am selecting the X-Plane main folder each time as per the installer instructions and my internet service is solid. Attached is the error message I get and my system info if that helps. Thanks in advance for any help I can get! Jim

-

jimvanzino joined the community

-

Trying to fly the SR22 Entgra after update to 12.4. Uninstalled inclded with the X-aviation download and reinstalled the aircraft today. Same results. I've attached the log for your veiwing. It appears to be a fault with an embedded plugin with the aircraft. Loading G:\X-Plane 12/Aircraft/X-Aviation/SR22 Series Entegra/TorqueSim SR22 Entegra/plugins/sr_systavi/resources/airspace/france.txt --=={This application has crashed!}==-- Log.txt