richjb

Members-

Posts

160 -

Joined

-

Last visited

-

Days Won

11

Content Type

Profiles

Forums

Latest X-Plane & Community News

Events

Downloads

Store

Everything posted by richjb

-

Insufficient Rudder Authority During V1 Cut (Engine Failure at V1)

richjb replied to richjb's topic in Technical Support

Thanks! Rich -

Insufficient Rudder Authority During V1 Cut (Engine Failure at V1)

richjb replied to richjb's topic in Technical Support

As a follow-on and to eliminate potential hardware controller issue, removed my rudder pedals from X-Plane and assigned a key command for left and right rudder. I did another set of V1 cuts using the keyboard to input full rudder. Same issue, not enough rudder to keep the nose from yawing into the failed engine, to keep the nose straight, and keep the skid/slip indicate (i.e., the doghouse) centered. I looked at the X Plane settings to see if rudder authority could be increase. Nothing found. Is rudder authority, force, etc., something that can be corrected in an upcoming update? Thanks! Rich Boll -

These references might also help: FAA Flight Planning Information | Federal Aviation Administration Rich Boll ICAO_Flight_Plan_Filing.pdf Flight_Plan_Codes_vs_Opnl_Auth_v8_Final_June_2020.pdf

-

Recommended joystick sensitivity curve ?

richjb replied to chock767's topic in Flying the Challenger

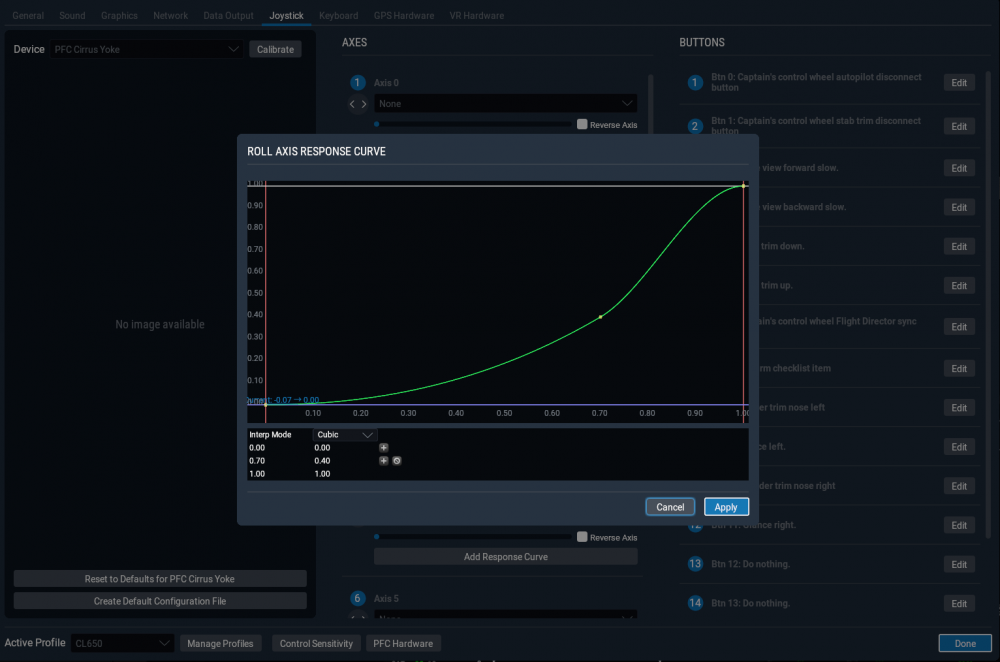

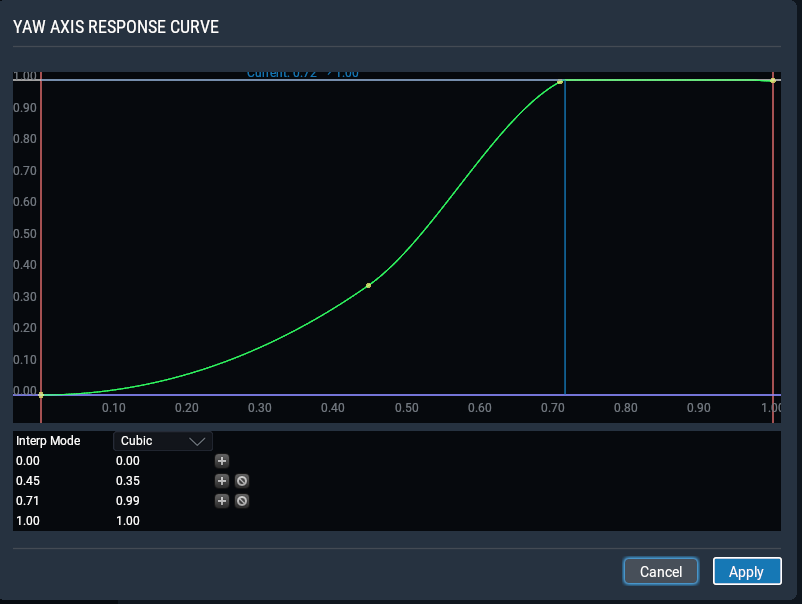

Hi Pils, I worked with the joystick curves tonight. Control Sensitivity and Stability Augmentation were all set at zero: My PFC Jetliner Yoke has a decent fore/aft range on it in elevator control, so I did not put that much of a response curve into the Pitch Axis Response Curve: The control wheel; however, has a much smaller range compared to the airplane/simulator. I followed Austin's example and used the in-sim control wheel displacement against my Yoke displacement as I moved the ailerons left and right. The ratio is 70:40 for roll axis and 60:40 for pitch axis. For the yaw axis, I was trying to replicate the maximum input I can get from my FlightLink rudder pedals: Full right rudder gives only a 70:100 ratio. Left rudder was a little better at 92:100 ratio. In neither case can get a 1:1 ratio. I have calibrated and re-calibrated my rudders. Any suggestions? As result, I set the Yaw Response Curve to a 70:100 ratio just to make sure that I'm getting full airplane/sim rudder with full rudder on my joystick. Alas, it did not fix my V1 cut issue. With full rudder, climbing out at V2 speed, the slip indicator in the Doghouse is still 3/4 to 1 full displacement when it should be centered. I'm going to have throw that one back you folks because I can't figure out how to fix it. With these response curves in roll and pitch, the airplane does fly better. I would like to try this configuration out in some windy days, and I bet KICT will oblige me soon enough. Thanks for your comments and help! Rich -

Recommended joystick sensitivity curve ?

richjb replied to chock767's topic in Flying the Challenger

Here's Austin's recent video on the subject: -

Recommended joystick sensitivity curve ?

richjb replied to chock767's topic in Flying the Challenger

Thanks PIls! I appreciate the heads up on the stability augmentation X-Plane doesn't provide a lot explanation about what these do. I'm trying to come to sense with X-Plane in this regard for all airplane models, not just HS CL650. I flew the FlyJ B737 the other day and on final approach it was atrocious. FWIW, I have the same issues in MSFS 2020. I like to think I have good set up. I have PFC Jetliner yoke, FlightLInk rudders, a B737 Jetmax throttle quadrant, and various Go-Flight modules (MCP Pro, EFIS, and LGT-II, and NAV-COM radio stack). if my wife knew what I spend, I would be shot! The Yoke and rudders are getting a bit long in the tooth, and I am eyeing a Brunner force feedback rudder. By in larger, though, I think I have pretty good equipment. I have tried to set the response curves, flattening them as you describe. The problem is that I always get some undesirable effects as you use more control force deflection. It's probably something I need to play with more as I am a X-Plane newbie, or at least so in terms of how much I have played with FSX and P3D in the past. I have to wonder if some of my issues with V1 cuts in HS CL650 are the result of the fact that I cannot get full rudder deflection in the X-Plane calibration. Moving the rudder full left and right, the calibration never goes all the way up to the upper right hand corner. I'm always somewhere down in the upper right third of the screen. however, using the control page on HS CL650, it does appear that I'm getting full rudder deflection. Same when I open the Developer's flight control screen. I'm hoping that XP12 will address some of these issues. Auston alluded to this in some of his videos. Thanks again, Pils! Happy flying! Rich Boll -

Recommended joystick sensitivity curve ?

richjb replied to chock767's topic in Flying the Challenger

Working on it. Like you, I find the aircraft overly sensitive with small control movements. I am not certain if it's a HS CL650 issue or an X-Plane issue. I have tried several different curves and stability augmentation settings. I have watched the X-Plane video by Austin. I'm playing a bunch of different configurations. Still playing... I have always found any X-Plane aircraft to be somewhat oversensitive. FlightDeck2Sim's commented on this as well and had noted that some aircraft have a significant, noticeable delay between elevator control movement and actual elevator movement. He commented on this in the FlyJ B737-200 on a recent live stream flight in Saudi Arabia,and made the comment that he has noticed it in other X-Plane aircraft as well. I do not know whether this applies to HS CL650. I raise it here because he's a pretty well respected source for real world flying and simulator flying and his reflections on X-Plane aircraft resonates with my experience. I may have 12,000 hours and 9000 hours in turbojets, but no one knows me from Adam. Not taking anything away from HS CL650. It's the best flight simulator aircraft for any platform (XPlane, MSFS 2020, FSX, P3D)...period! Rich Boll -

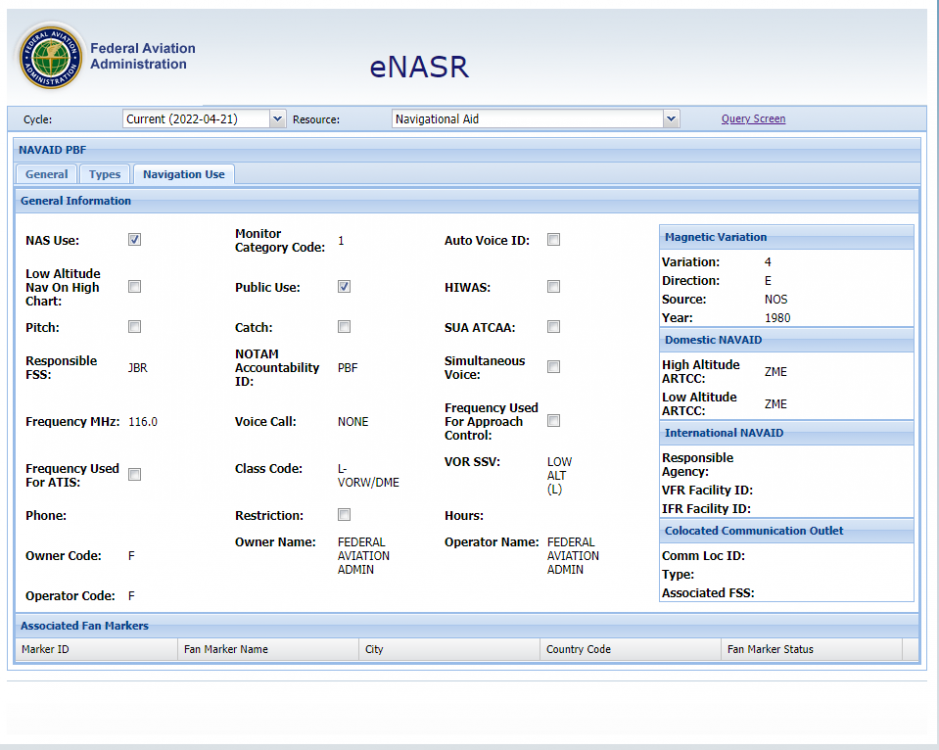

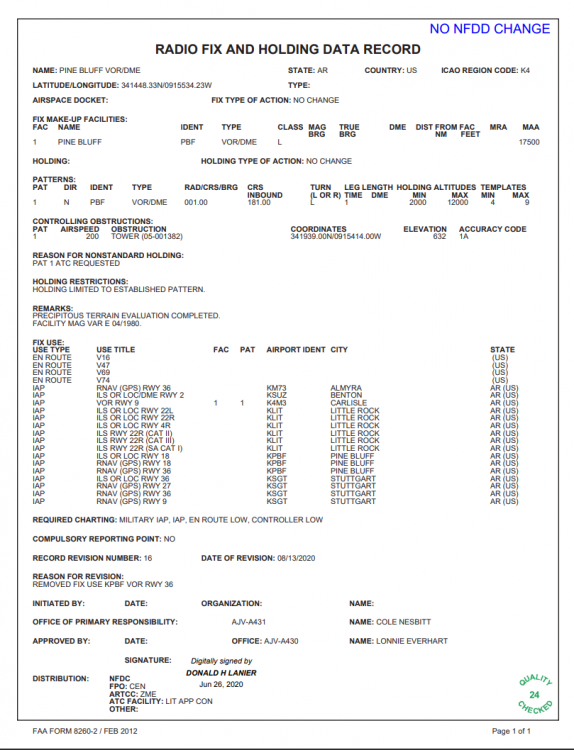

Part of the problem is that the world is tipping on its side, and it's happening faster each year. Doesn't bode well for those southern vacation spots in a hundred years or so! ;-) The reality is that in the US we're not updating the VOR MagVars that often, part it is due to the ongoing decommissioning process in the US called the VOR Minimum Operational Network. Adjusting for MagVar requires changes to the actual VOR and the FAA is just behind the problem as they work through the VOR MON program. Here's an FAA Aeronautical Charting Meeting agenda item discussing the MagVar discrepancies that can happen between conventional procedures and the MagVar in the FMS: Hist_11-01-296 (faa.gov). Here's one on use of MagVar on DMEs: 14-02-284-ACF_DME_Facilities.pdf (faa.gov) This InFO explains the differences between conventional procedures and FMS tracks: InFO 12009, Magnetic Variation Differences Between Ground-Based Navigational Aid (NAVAID) (faa.gov) Much of the issues are involved outdated MagVar tables in the IRU, collected by the field and used in procedure development and documentation along with the procedure not being updated. There's been much talk in in various industry groups, including the Aeronautical Charting Meeting, which is going on as I type, about moving towards using the Airport Reference Point as the source MagVar for all instrument procedures tied to that airport. All of these issues go away if move to True. Magnetic track, course, and heading is presented solely for pilot convenience. The FMs and IRU computes everything in True, then converts it to Magnetic so it agrees with the magnetic compass. Going to True would mean no more runway repainting due to runway number changes resulting from MagVar changes. It would mean no more mis-match between procedure tracks as MagVar changes. Rich

-

Hi Skiselkov, Explanation makes perfect sense and the issue is actually quite well known in the real aviation community. MagVar discrepancies between the aircraft, the IRU, the procedure source (i.e., the 8260 Forms) have been a known source of problems on instrument procedures for a long time. It resulted in a real mess in ORD last Fall on the STARs. it's also the the reason why we lost a bunch of CAT II and CAT III approaches in the US a few years ago for older airplanes where the The fact that you have modeled these MagVar discrepancies between the avionics and the procedure source data (i.e., 8260 Forms in the US) is another feather in your cap. I've never seen this discrepancy modeled in a flight simulator product before, so I did not even occur to me that this could be the issue. Been a lot of talk of going to True in various part of the world. Airbus and Dassault are pushing for it. Again, excellent job with the HS CL650! I withdrawal the issue. Thanks! Rich Boll

-

So, this is a geeky issue that you may not see unless you're flying VOR or ILS green needles. I was flying the ILS or LOC Rwy 18 approach to Pine Bluff, AR (KPBF) looking at the teardrop course reversal. I was testing fly it in response to question I was asked, and I needed to fly it using just the VOR and the ILS green needles. A technique we learned a long time ago was when the CDI was centered, fly a heading that keeps the track indicator on the head of the CDI needle. That way, your track is following the course set in the CDI and you should not drift since the track indicator donut would be showing zero drift angle. Per the Collins CL650 manual, the track pointer shows the ground track over the earth. So, if it is aligned with the course arrow when CDI is centered, there should be no drift and CDI should remain centered. This is of course if you are using HDG mode to track the CDI instead of NAV/VOR mode, which is sometime easier if you're flying these types of approaches. Not everything is LNAV and VNAV! While flying outbound on the teardrop course reversal (PBF R-022) for this approach, I was able to find a heading that kept the CDI centered. However, the track indicator donut was several degrees off to the right: You will have trust me that did fly a heading long enough to find one that kept the CDI centered for a period of time. With track pointer showing as it is above, my ground track should be tracking to the right and away from the PBF R-022, and the CDI needle should be moving to the left. It's not. The CDI is remaining centered. The MagVar for KPBF is 4 degrees East. Is it possible that in HS CL650 the Track Pointer is showing True Track instead of Magnetic Track? It looks like the track donut is at 026 degrees, just ever so slightly left of the heading bug of 027. Going by the saying "east is least", subtract 4 degrees from a true track of 026 and you get 022, which is the PBF radial I am tracking. That's the only thing that comes to mind as to what might be happening here. If needed, I can try some more experiments. However, at first glace it looks like the track donut is showing True Track instead of Magnetic Track. Thanks for your assistance! Rich Boll

-

V-SPEEDS DELETED after APPROACH speeds selected

richjb replied to richjb's topic in Technical Support

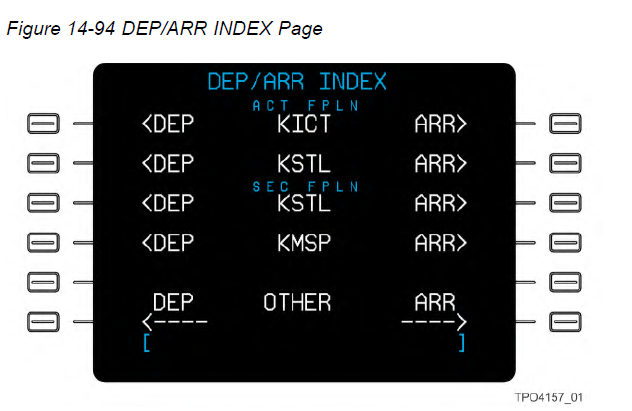

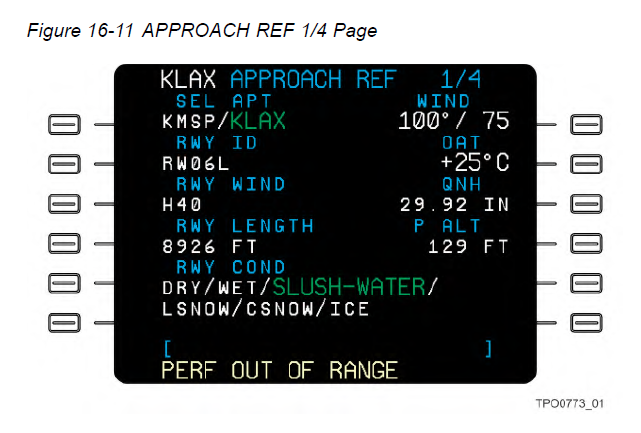

Hi Pils, I contacted my retired Collins customer liaison/training pilot about this behavior. He gave me a good explanation of how this works. When you enter the ORIG and DEST airports, you create two DEP/ARR page selection "silos", one for the ORIG airport and one for the DEST airport. On the ground, or airborne within 50 miles of the ORIG or less than 1/2 way between the ORIG and DEST airports if the distance between the two is less than 100 miles, the first press of the DEP/ARR key bring up the DEPART page (if on ground) or the ARRIVALS page (if airborne) for the ORIG airport. The second press brings up the DEP/ARR INDEX Page, where you select DEPARTURE or ARRIVAL page for either the ORIG (first option) or the DEST (second option): In the air, the first press of the DEP/ARR button bring up the ARRIVALS for the ORIG airport is less than 50 miles or less than 1/2 of the distance between the two airports if they are separated by less than 100 miles. More than 50 miles or more than 1/2 of the distance between the two airports, it brings up the ARRIVALS page for the DEST airport. These are the two "silos" ARRIVAL options that can be selected once airborne. The engineer's intent was that in an emergency return the departure airport, the pilot will want quick access to the approaches available at the departure airport, which is why the first key press of the DEP/ARR key brings up the arrivals for the ORIG airport. The closer the two airports are together, the greater the chance the airport selection can confusing. For example, a short flight from Wichita - Eisenhower (KICT) to Wichita - Jabarra (KAAO), separated by about 10 miles. After takeoff and while getting radar vectors to Jabarra, if you load the approach and complete the landing data on the APPROACH Performance page, but then for whatever reason start getting vectors back to towards KICT and the distance to KICT becomes closer than KAAO, the FMS can think that you're now trying to return to KICT, the FMS has moved back to the ORIG silo and the APPROACH Performance page has moved back to the ORIG airport and as result has dropped the V-Speeds and performance data. If you look on the APPROACH REF page of the FMS, there are two airports - the ORIG and DEST: The FMS has gone back to the ORIG airport in this case and dropped the V-Speeds. It gets more confusing when you're in a round-robin training mode, for example the ORIG and DEST airports are both "KICT". in the air If you press the DEP/ARR key, the FMS brings up the ARRIVAL page for the ORIG airport, KICT. If you load the approach and then complete the APPROACH REF page based on the ORIG airport ARRIVAL loaded in the FMS, as you fly downwind for the return approach, at some point the FMS will think it's more than 1/2 way away from the ORIG airport and switch to the DEST airport's silo, and its APPROACH REF page is blank because you have not entered any data for this runway. The FLT PLN and LEGS page still show the approach you selected using the ORIG airport, but the Performance page has switch from the ORIG airport to the DEST airport. If you press the DEP/ARR key twice to bring up the DEP/ARR INDEX page, select the approach from the DEST airport (i.e., the second airport in the list) AND....you select the DEST airport on the APPROACH REF page (i.e. the second airport option - in the example above that shows KMSP/KLAX, select "KLAX") you are less likely to have the V-Speeds dumped. He says it's not impossible, but much less likely. Again, if you turn back around and it thinks you're going back to the ORIG airport, the FMS can switch back to the ORIG airport performance page. The behavior I was seeing in HS CL650 did initially mimic this behavior, and it's what I have seen in the Level D CL300 simulators when we're doing circuit training, i.e. multiple back to back approaches. What I was also seeing in HS CL650 was the FMS drop the V-speeds multiple times on final. My contact says that should not happen. As long as you're in one branch or "silo" of the ORIG or DEST airport, the V-Speeds should not drop unless you switch silos, which is not likely as your final approach and you've set one or the other branch/silo - the ORIG or DEST. Please let me know if this makes sense? Thanks! Rich Boll -

FMS-Calculated Climb Gradient Configuration/IAS

richjb replied to dlrk's topic in Flying the Challenger

The ODP or SID is not intended for OEI terrain and obstacle clearance since the criteria does not consider both the actual takeoff flight path of the aircraft following an engine failure nor does the climb gradient on an ODP or SD account for all obstacles that much cleared to meet the operating rules. An ODP or SID provides obstacle clearance with all-engines-operating because that's what its criteria assumes. Make sense? With the proper obstacle information concerning obstacle height above the runway and distance from reference zero, the FMS calculator can be used to calculate OEI takeoff obstacle clearance in accordance with the operating rules. Here's an important caveat. You need the relevant terrain & obstacle data and collecting that data no small feat. There are multiple data sources that need to be consulted, which is why the airlines have performance engineering departments dedicated to that task. For the business aviation community, we have contract providers such Aircraft Performance Group, ASAP Inc., Aerodata (now owned by Garmin), and Jeppesen OpsData through ForeFlight that provide this type of engineering support, and provide takeoff performance/obstacle clearance data in the form of airport runway analysis. As real CL300/350 pilot, I would never attempt to gather the obstacle data from the various sources and use the FMS calculator, in the same way that I would never attempt collect obstacle data and build my own instrument approach procedure to a runway. The FAA is expert in building instrument flight procedures and these performance engineer providers are the experts in airplane performance and engine failure escape procedures. I was never really quite sure why the FMS manufacturers (OEMs) put the obstacle clearance routine in their FMS. It's not unique to Collins. It's in the Garmin 5000 as well. If you had one known obstacle that you wanted to clear, one that as not accounted for in your contractor-provided analysis, for example a temporary obstacle, then yes, I could see a use for it. Although in 18 years of flying Collins FMS equipped aircraft, I have never used it other than for experimentation and familiarization. Rich -

FMS-Calculated Climb Gradient Configuration/IAS

richjb replied to dlrk's topic in Flying the Challenger

Yes, an ODP is an IFR procedure used to avoid terrain. However, it's the context that is important to understand. You have asked a question that has caused and continues to cause much confusion among pilots and their training providers. It is one reason why the FAA produced the set of training videos on transport airplane performance, which I have linked in another post. In the US, the certification & operating rules for transport category airplanes, which apply to the CL650, date back to June 1941. That's before Pearl Harbor! While the certification rules have been updated to reflect changes in airplane technology, namely the introduction of turbojet airplanes in the 1950s, the operating rules remain largely unchanged. For these airplanes, a basic concept applies. When operated in commercial service (in the US, under part 121 or part 135 - the later applying to the CL650), The concept is that the airplane can experience an engine failure prior to V1 speed and stop on the remaining runway available, or experience an engine failure after V1, continue the takeoff, and the entire flight to the destination airport and alternate airport, if required, without hitting an obstacle. If you read the operating rules, this concept is clear. And this basically how obstacle clearance was addressed even for a normal IFR takeoff all-engines operating since it was always considered, and still is, that the obstacle clearance following an engine failure is more critical than it would be for a normal takeoff. The FAA did not begin to address obstacle clearance on an IFR takeoff until a major re-write to their instrument procedure criteria in 1967, which gave us the US Standard for Terminal Procedures, or US TERPS. Even with this change, it took until the mid-70s until the instrument departure procedure criteria resembles what it looks like to today. At that time, they looked at the possibility of including a OEI requirement to the criteria. After much input from the industry, including the airlines which had been developing OEI obstacle avoidance procedures since the 40's and objected to this addition, the FAA decided that the IFR takeoff and departure, and all of TERPS, will only address only normal aircraft operation. The Title Page to the US TERPS Order 8260.3E states the following: This order prescribes standardized methods for designing and evaluating instrument flight procedures (IFPs) in the United States and its territories. It is to be used by all personnel responsible for the preparation, approval, and promulgation of IFPs. These criteria are predicated on normal aircraft operations and performance. In paragraph 2-1-4 e, the Order further states: e. Extraordinary circumstances, such as a mechanical or electrical malfunction, may prevent an aircraft from achieving the 200 ft/NM minimum climb gradient assumed by TERPS. In these cases, adequate obstacle clearance may not be provided by published IFPs. Operational procedures contained outside TERPS guidelines are required to cope with these abnormal scenarios Those "operational procedures contained outside of TERPS guidelines" are the operating rules with respect to OEI takeoff and en route obstacle clearance. In short, the criteria used to develop an ODP or a SID assumes a normally operating aircraft, with all engines operating. When the engine quits, the ODP or SID no longer applicable because the criteria doesn't use the same assumptions that the airplane certification criteria uses to construct the OEI takeoff flight path shown in the excerpts above in the AFM. For example, an ODP or SID's climb gradient assumes a linear climb to the climb gradient termination altitude. Actually, it's a surface that cannot be penetrated from above. The OEI takeoff flight path is not linear, it's a segmented path, and obstacle clearance needs to be assessed at each point along that path. Also, there are obstacles that are not considered by the ODP or SID climb gradient that could still be factor following an engine failure. These are known as "low, close-in obstacles". Low, close-in obstacles are obstacles that lie right off the end of the runway. They require an IFR climb gradient greater than the standard 200 ft/NM, but that climb gradient would only be required to a height of less than 200 feet above the runway. Rather than publishing the climb gradient, they publish the obstacles and their location relative to the runway end so that the pilot can take whatever action they deem appropriate to miss them. One of my favorite examples of how low, close-in obstacles can affect takeoff performance is Hutchison KS, runway 13 at 40C (104F). Yes, living in Wichita which is just down the road, 40C in the summertime is not unusual. if you run takeoff data for just the runway length and the standard 200 ft/NM or 3.3% climb gradient off runway 13, you find a weight that is greater than the weight limit shown on a takeoff runway analysis that accounts for these obstacles. Therein lies the problem for commercial operators who relay solely on IFR ODP or SID climb gradient. They takeoff at weight in excess of that required by the CFRs (e.g., 14 CFR 315.379 d ii) and if the engine fails at V1, they could find themselves tangling with the obstacles while the landing gear is retracting. Private operators who not governed by these OEI takeoff obstacle clearance rules often abide by them voluntarily. The US Aeronautical Information Manual has the following statements in Section 5-2-9 concerning ODP and SIDs: 2. ODPs, SIDs, and DVAs assume normal aircraft performance, and that all engines are operating. Development of contingency procedures, required to cover the case of an engine failure or other emergency in flight that may occur after liftoff, is the responsibility of the operator. (More detailed information on this subject is available in Advisory Circular AC 120−91, Airport Obstacle Analysis, and in the “Departure Procedures” section of chapter 2 in the Instrument Procedures Handbook, FAA−H−8083−16.) NOTE− Compliance with 14 CFR Part 121 or 135 one−engine−inoperative (OEI) departure performance requirements, or similar ICAO/State rules, cannot be assured by the sole use of “low, close−in” obstacle data as published in the TPP. Operators should refer to precise data sources (for example, GIS database, etc.) specifically intended for OEI departure planning for those operations. (d) Consider the effect of degraded climb performance and the actions to take in the event of an engine loss during the departure. Pilots should notify ATC as soon as possible of reduced climb capability in that circumstance. NOTE− Guidance concerning contingency procedures that address an engine failure on takeoff after V1 speed on a large or turbine−powered transport category airplane may be found in AC 120−91, Airport Obstacle Analysis. For those folks flying in Europe and throughout the world, ICAO PANS-OPS contains similar statements. Obstacle clearance following an engine failure on takeoff is the responsibly of the operator and is outside the scope of US TERPS and ICAO-PANS OPS. How these OEI takeoff obstacle avoidance procedures are developed is described in FAA AC 120-91A: AC 120-91A - Airport Obstacle Analysis – Document Information (faa.gov) I hope this helps explain the difference. Rich Boll -

V-SPEEDS DELETED after APPROACH speeds selected

richjb replied to richjb's topic in Technical Support

Hi Pils, So, I did find the reference in the CL650 FMS book....and in the CL300/350 FMS book! Let me see what I can find about this behavior from my list of gurus. Rich -

FMS-Calculated Climb Gradient Configuration/IAS

richjb replied to dlrk's topic in Flying the Challenger

Typically, the normal takeoff procedure will result in you climbing well above any climb gradient requirement on a SID or ODP. If there is no SID or ODP, then a 200 ft/NM climb gradient is required. For takeoff the minimum takeoff speed, all engines operating is V2+10. That provides you sufficient stall margin with 30 degree bank. I can get into a whole bunch calculations, etc. concern how to compute a percent climb gradient and rate of climb when you have a SID or ODP climb gradient in feet/NM. The Collins Proline 21 has a neat feature that makes this easy. Use the Flight Path Vector. If you have a SID with a 400 ft/NM climb gradient, after takeoff make sure that the Flight Path Vector remains 4.0 degrees or more above the horizon. The climb gradient in feet/NM roughly equals the flight path angle in degrees - See the US Government Terminal Procedures Publication Legend below. Turbojets are generally capable of meeting a 500 ft/NM climb gradient on a SID or ODP without much further consideration up to 1500' above the airport elevation simply on the basis of the aircraft's OEI takeoff climb requirements. Again, it is not required nor expected that you meet the SID or ODP climb gradient with OEI. Initially, rotate to the TO command bar pitch attitude. That's to prevent on over-rotation accident. After the aircraft is accelerating, then use FLC and 200 Kts to continue the climb. See FCOM 1 takeoff procedure below. Rich -

FMS-Calculated Climb Gradient Configuration/IAS

richjb replied to dlrk's topic in Flying the Challenger

I neglected to answer your questions on approach climb and landing climb gradients, and what they are based on here. What we have in the FMS is a good hearted attempt to provide information to the pilot that is really relevant to performance. I'll explain in a moment. Approach climb is certification performance requirement. It is the climb gradient available with the aircraft in the approach configuration (flaps 20 for the CL65), landing gear retracted, with the thrust set to go-around thrust, a climb speed not more than 1.4 VSR (reference stall speed), and based on the published AFM procedures for a OEI go around. The minimum climb gradient is 2.1%. Landing climb is also a certification performance requirement. It is the climb gradient available in the landing configuration, landing gear extended, at VREF speed, and with thrust available 8 seconds after go-around thrust is selected (which may be less than the actual go-around thrust as the engine spools up). The minimum climb gradient is 3.2%. These two climb gradients are "certification requirements" and established as part of the maximum allowable landing weight for the aircraft in the AFM Limitations Section. For the CL650, they are published in the AFM Performance Section, but incorporated into the Limitations section by reference. The operating regulations for flying the airplane require that airplane's takeoff weight, less fuel and oil consumed in flight, allow the airplane to arrive at the destination airport and alternate airport (if applicable) at weight that is less than the maximum allowable landing where the approach climb and landing climb requirements are met. The AFM has an Approach and Landing Climb weight limit chart. That chart is incorporated into the FMS performance module. When you complete the APPROACH performance page, if you are overweight, for the information that you entered for landing, the FMS will tell you: MLW Maximum Landing Weight (MLW) is determined by the most restrictive selection among the following: structural limit weight, climb performance limit weight, and runway length limit weight. If MLW is unable to be computed, the MLW data field is blank. When landing weight is greater than maximum landing weight, the MLW shows in yellow. In addition, a CDU message CHECK APPROACH PERF shows under these conditions. MLW values are synchronized on the APPROACH REF pages All of the one-engine-inoperative (OEI) takeoff, OEI approach climb, and all-engines-operating (AEO) Landing climb gradient requirement are not true climb performance requirements. They are statements of excess energy available to the aircraft in the stated configuration, at the applicable speed, and with the available thrust. That excess energy can be used to climb the aircraft or accelerate it, as appropriate. Further, the climb gradient values are "spot gradients" that a valid only at particular point in takeoff or landing phase. For example, the 2nd segment climb gradient data and climb gradient value determined is only valid at the exact instant that the landing gear is fully retracted after takeoff at V2 speed, with the takeoff flaps, and with takeoff thrust with one engine inoperative. Once you leave that "spot", the climb gradient decrease. For 2nd segment, or reference climb gradient as Bombardier calls it, the decrement in climb gradient that occurs as the aircraft climbs is built into the two flight path charts that I posted earlier, and is why the takeoff flight path charts are used to determine obstacle clearance rather than computing a "rise over run" climb gradient requirement, e.g., 300' obstacle, 1 NM away, minimum climb gradient 300 ft/NM or 4.9%. That doesn't work out that way when you use the flight path charts for the reference climb gradient required for obstacle clearance. Using the flight path chart, the reference climb gradient required to clear a 300' obstacle 1 NM (6076 feet) from the runway end (assuming takeoff distance required is equal to the runway length) is 5.3% (see example). As long as your Maximum Landing Weight is not showing overweight in the FMS for the conditions you entered, follow the AFM go around procedures, and you will meet the performance requirements. For OEI go around, climb a speed not less than VAPP and for all engines missed approach, a speed not less than VREF. However, at most landing weights, you'll be well below these limits and the AFM procedure will likely result in speeds being attained above these limits at the recommended go-around pitch attitude. If that's the case, take the extra speed. Rich Boll -

FMS-Calculated Climb Gradient Configuration/IAS

richjb replied to dlrk's topic in Flying the Challenger

So, I'm going to preface this by saying that this is how it works in the Challenger 300/350, which I fly.... I don't fly the 650 and have not yet looked that close at it, but I have no reason to believe Bombardier and Collins would approach this any differently between airplanes. TAKEOFF REF page 3/4 presents several options that you can enter (see attachment). One is OBST HT and OBST DIST. LEVEL-OFF HT is also included. You enter the obstacle height and distance from "reference zero", which is the end of the takeoff distance to 35 feet (dry) or 15 feet (wet). Because they measure the obstacle's distance from reference zero, unused runway must be added to the obstacle's distance from the end of the runway. This also is a clue as to what data Collins and Bombardier are using with the calculation. This "Obstacle Clearance Calculator" that Bombardier & Collins are using references the AFM Performance Section's Flight Path charts, both close-in and distant. These charts have been digitized and stored in the FMS's performance module. The Obstacle Clearance Calculator is using the obstacle distance from reference zero and the obstacle's height above the runway elevation to determine the required Reference Climb Gradient necessary to clear the obstacle. The reference climb gradient is equal to the 2nd segment climb gradient achieved after the landing gear has retracted, but the flaps are still in the takeoff configuration, and the thrust is at the takeoff thrust setting. The airspeed is V2 speed. Further, all of this data is based on an engine failure at VEF or the presumed engine failure speed, which is typically 1 second prior to V1 speed with the pilot electing to continue the takeoff. The calculator will also calculate the level-off height necessary to clear the obstacle in this second segment climb, after which the aircraft can level, accelerate, and clean up to VFTO speed. That is of course assuming that this is the most critical obstacle for the takeoff. The FMS defaults to a 1000' level-off height but can extend to a higher level off height as needed. It can also be set to minimum height of 400'. The AFM's Flight Path graphic illustrates the profile that is flown. The FMS Takeoff Ref Page 3/4 is calculating the required climb gradient flight path during the first segment climb and the second segment climb up to the calculated Gross Level-Off Height. The required Reference Climb Gradient will ensure that the Net Takeoff Flight Path clears the obstacle. The actual, or "Gross" flight path will clear the obstacle by much more, approximately 0.8% of the distance traveled from reference zero. The Obstacle Clearance Limit weight is calculated based on the data you entered. The system can work backwards, too. You can enter a required climb gradient in the REQ CLB GRAD field and have it calculated the limit weight. The problem is that we don't know that value. It's not the SID or ODP climb gradient since 1) those are based on all-engines operating, normal takeoff performance, and 2) the reference climb gradient data in the FMS is based on the limited scope of the two flight path charts, close-in and distant. On the distant chart, once you get beyond that vertical line on the right of the chart, you're exceeding the 5 minute time limit for takeoff thrust. If you want to know how to comply with a SID or ODP climb gradient, I refer you to this FAA Information for Operators (InFO) bulletin: InFO 18014: Compliance with Title 14 of the Code of Federal Regulations (14 CFR) Part 97 Instrument Flight Rules (IFR) Departure Procedure & Missed Approach Climb Gradient Requirements (faa.gov) The more I look at the CL650's FMS guide and the AFM, the more that I am fairly certain that it works the same way as in our CL300/350. We do not use this FMS feature. Rather we along with most other operators are now using some type airport runway analysis. In the flight simulator world, these are the type of takeoff performance reports generated by the TOPCAT system: FlightSimSoft.com. Unfortunately, we're not likely to see the CL350 added to the list of airplanes supported. I hope this helps! Rich Boll -

FMS-Calculated Climb Gradient Configuration/IAS

richjb replied to dlrk's topic in Flying the Challenger

Not necessarily... I'm speaking for the US now. Every airport with an instrument approach is assessed for an IFR departure. If you want to know the details, you can read about it in the FAA's Instrument Procedures Handbook: Instrument Procedures Handbook (IPH) | Federal Aviation Administration (faa.gov). If there are no obstacles or terrain affecting an IFR departure from the runway, the pilot is free to turn in any direction after climbing to 400' above the runway elevation and proceed on their way. It's important to note that this "diverse" departure assessment is valid only out to 25 miles in nonmountainous areas and 46 miles in mountainous areas. If obstacles or terrain effect the IFR departure, then takeoff minimums and/or an obstacle departure procedure (ODP) is published for that runway. The ODP can be nothing more than listing of low, close in obstacles that must be seen or otherwise avoided on takeoff. These are not a factor in turbojet takeoffs as long as all engines are operating. The takeoff performance requirements mean that you are well above most of these obstacles by the time you cross the end of the runway. The ODP can consist of a higher than standard climb gradient that will clear obstacles or higher than standard takeoff minimums that allow the pilot to see an avoid the obstacles. The ODP can also turn restrictions, such climb on a heading to an altitude before turning in a specific direction. Finally, the ODP can consist of specific routing to avoid obstacles, to include a climb in holding until reaching a safety altitude. A SID is nothing more than an abbreviated ATC clearance in charted form. The route is evaluated for obstacle clearance, and if assigned by ATC you fly it instead of the ODP. If no SID is assigned, but takeoff minimums and/or an ODP is published for the runway, and you are an FAA certificated operator (i.e., airline or charter operator), then you're required to fly the ODP. If there is no SID or ODP, then you are free to turn in any direction and proceed on your way to your first en route fix. However, again you are responsible for terrain and obstacle clearance once you're more than 25/46 miles from the airport. Hope this helps, Rich Boll -

V-SPEEDS DELETED after APPROACH speeds selected

richjb replied to richjb's topic in Technical Support

I did a short test flight from KICT to KHUT. I noticed there. I flew a second flight from KPDX to KMFR, but did not see it on that flight. Yesterday, I did a V1 cut at KICT (see my post on that issue) then did an immediate return to KICT. I saw it six times on that flight including at least twice on final approach inside the FAF. I don't think that should happen. I'll check my manuals. I have set of 650 books for 2018 period now. Thanks again for your help! Rich -

V-SPEEDS DELETED after APPROACH speeds selected

richjb replied to richjb's topic in Technical Support

Hi Pils, I say that it could be, but I don't recall it being as a frequent of an occurrence with1.4.x. If you provide me the page reference for above, I'll try to dig further into it. thanks, Rich