g650flyer

Members-

Posts

46 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Latest X-Plane & Community News

Events

Downloads

Store

Everything posted by g650flyer

-

Still no decoder ring for flap settings with these charts????

-

Did anyone get to the bottom of the flap settings driven by the charts? I'm sure they are in the aircraft manual, maybe LES left them out when creating their own document

-

Don't know if it's been mentioned before, but if i edit the cruise, DES or route page speed, the speed on the page shows 0. The aircraft will actually adjust to the speed I input when i enter 300/ etc., but will not display the actual speed I entered. Only a zero.

-

Let me know how it works out

-

Don't fret, just a couple of techniques and you will have centerline nailed. I've seen people have this issue in the real jet. I always teach that regardless of the seat you are in, keep your inboard foot on the runway and centerline. This works well in the airplane, but in your case, it won't do much. My technique for flightsims is to use the ADI. Draw an imaginary line from the runway and keep it right through the center of your ADI. This works like a charm, but you have to adjust it with crosswinds. I'm a wing low type of guy when dealing with crosswinds. Initially, you will have to be able to look at the runway and judge a drift killed heading to track it. At about 400ft, I use rudder to align the aircraft with the runway and center it using the ADI. Use the ailerons to move left and right and adjust for the rolling moment from the rudder. As you gain more detail as you approach the runway, fight for centerline using small inputs. Keep the aircraft aligned with the rudder and keep those crosswind controls in. After touch down, get the nose to the runway for assistance from rudder pedal steering. The biggest mistake I see in the real jet is that guys/gals will give up crosswind controls after touch down. Even though the jet is on the ground, it's still flying. If the nose isn't aligned with the runway, you are going to drift requiring some rudder correction. Where ever the jet is pointed, that's where its going. This is why I favor wing low versus the last minute rudder kick. I don't want to figure out optimum rudder and aileron input right before touch down, I have other things I'd rather be thinking about. The type jet I fly weather vanes easily after touch down. Ground spoilers and reversers aggravate the situation by diminishing aileron input and rudder effectiveness. I much rather get my crosswind controls warmed up at 300ft, have it wired through touch down and ready to feed in more control. I also noticed a little wing wag going on in your video. Once you start using the ADI technique, it should cancel it out. Just remember, small inputs and small corrections and you will be fine. Yea, kiss landings work on long runways, but it creates a habit pattern. You easily get accustomed to working a greaser, which leads to easily applying it in wrong situations subconsciously. You will start naturally landing long without noticing it. Here's a good example. When I flew DC10s, A technique was to use only the number 1 and 3 reversers when landing in austere low support areas. The idea was if the number 2 reverser got stuck out, there would be no support to get a guy up to the engine to stow and lock it out. Over time, people would start doing this at every airport. It became a habit. During an evaluation, a guy landed on a short wet runway and only used 1 and 3. I gave him a minus in the landing area. He didn't intend to, in fact he briefed he would use all 3. Unfortunately, it became his bad habit. This is why it's a good idea to always use the text book flare procedure. Once it becomes a good habit, you will stay consistent no matter how long or short the runway is.

-

Good question! Recent years have shown that the majority of over runs occur from aircraft that touch down beyond the 1500ft area. Touching down in the first third of the runway usually ensures stopping distance. In the aircraft I fly now, the minimum runway length is 5000ft. 1000 to 1500ft is within the first third of the runway. Touching down prior to the 1000ft point puts you in another risk area. Most aircraft have the glide slope antenna located in the nose. This means that if the threshold crossing height is at 50ft, your nose passes over the threshold at 50ft. Your tail and landing gear will be lower than that(imagine a long bodied aircraft). Imagine how low an aircraft has to be in order to touch down at the 500ft mark. You run the risk of clipping something. This is why flight manuals have you aim at the 1000ft mark. Some runways may have terrain and obstructions on the approach path. Now, here's another perspective. Though my minimum runway is 5000ft, every blue moon we may have to land on a runway less than 5000ft. Our guidance is that the runway has to be at least equal to or greater than landing ground roll plus 1000ft. To accomplish this, we have a procedure called minimum run landing. We fly the approach normally all the way down to 300ft. At 300ft, we shift our aimpoint from 1000 to 500ft down. Shifting to 500ft with a normal flare puts you down between the 500 and 1000ft point. The premise in this procedure is that the departure clearways are obstruction free up to 400ft. Of course you would have to verify and confirm that the intended runway clearway is obstruction free. In general, aiming at 1000ft down will get you down by 1500ft. When I flew DC10s, we would fly the visual glide path with one white and one pink. At 300ft, we would aim for the 1000ft mark. Rick

-

Greetings again, Just wanted to cover another topic in the tips saga. This time we will focus on landing. By the time you make it to the majors or the corporate world, most pilots are well established. By this point, most employers know that candidates have polished skills. The focus during the hiring process is personality, procedural/regulation knowledge and flight management. The most important aspect about flying is flight management. One important part of flight management is the landing phase. Believe it or not, the landing phase actually starts in preflight planning. Taking the time to become familiar with the airport, it's procedures, environment, weather, approaches and traffic flow is paramount. 100% of the field study is done during planning and a quick rehash is done before descent. You've heard numerous times that a great landing starts with a great descent. Before we get started, I'll give you an idea of the evaluation criteria I used when giving evaluations in my airforce days and currently. Area 15, VFR Pattern. Q. Performed traffic pattern and turn to final/final approach IAW published procedures. Aircraft control was smooth and positive. Constantly cleared area of intended flight. Q-. Performed traffic pattern and turn to final/final approach with minor deviations to procedures as published/directed. Aircraft control was safe but not consistently smooth and positive. Over/under shot final approach, but was able to intercept normal glide path. Adequately cleared area of intended flight. U. Did not perform traffic pattern and/or turn to final/final approach IAW published procedures. Displayed erratic aircraft control. Did not clear area of intended flight. Area 16, Landings. Reference Table 2.2 for grading criteria specific to landings. Specific items to evaluate include threshold altitude/airspeed, runway alignment, flare, touchdown, and landing in crab. Airspeed tolerances apply to computed threshold speed. Add 5 KIAS to all engines operating criteria for operations with an engine out criteria. Q Performed landings as published/directed IAW flight manual Airspeed +10 / -0 KIAS Touchdown Zone 1000-3000 feet Centerline +/- 15 feet left or right TCH +25 / -0 feet Q- Performed landings with minor deviation to procedures as published/directed. Landed in a slight crab Airspeed +10 / -5 KIAS Touchdown Zone 500-3000 feet Centerline +/- 25 feet left or right TCH +50 / -5 feet U Landing not performed as published/directed. Exceeded Q- criteria Area 17, Landing Roll/Braking/Reverse Thrust. Q. Performed as published/directed IAW flight manual. Braking action and reverse thrust actuation prompt and smooth. Q-. Performed landings with minor deviation to procedures as published/directed. Braking action and reverse thrust actuation unnecessarily delayed or not smooth. U. Landing not performed as published/directed. Braking or reverse thrust actuated prior to touchdown. Exceeded Q- criteria. Area 18, All Engine Go-Around (GA). Required in-flight, only if a GA or engine-out GA was not evaluated in the simulator (not required if area 20 is accomplished). Q. Initiated and performed GA promptly and according to flight manual and directives. Applied smooth control inputs. Acquired and maintained a positive climb. Q-. Slow or hesitant to initiate GA. Slightly over-controlled the aircraft. Minor deviations did not affect mission accomplishment or compromise safety. U. Did not initiate GA when appropriate or directed. Major deviations or misapplication of procedures could have led to an unsafe condition. These are pretty easy and as you can imagine, one U in one area or multiple Q- grading leads to a failed checkride. There are a total of 60 areas evaluated, I only listed the areas associated with landing. For starters, a good review and approach brief sets you up for a great landing. On average, a good point to start the brief is anywhere from about an hour from landing no later than 10 minutes from the descent point. Here is what I brief real world. 1. Approach Name (e.g. ILS 1L) or VFR Pattern 2. NAVAID Frequencies 3. Final Approach Course 4. Final Approach Fix / Glide Slope Intercept 5. DA / MDA / RA (Cat II ILS only) 6. TDZE / Min Safe Altitude / Trans Level 7. Runway lighting type 8. Missed Approach Instructions 9. Current WX and approach WX minimums / RAIM (if applicable) 10. Landing runway length vs. landing dist. 11. Stabilized Approach Criteria 12. Taxi Plan While being a one man/woman show, utilize the automation as much as you can. This give you the ability to monitor approach and stay progressive. I normally hand fly once I'm on the slope or descending out of MDA. One thing to remember is to make small corrections. Some people will preach pitch and power, but in the days of heavy iron, it's not as relevant. Once configured and on approach, your power should be stable. There are a few techniques for good power settings. The other day in the IXEG 737, I noticed that at 100,000 pounds, power with flaps 30 on the slope was about 62%. So, 10% of your gross weight + 52 is a good base line in this jet. 100,000 pounds = 10% of 100K +52 = 10+52 = 62% N1 as a base line for flaps 30 ref +5 on approach. In this case, my approach power is set and I don't want to touch it. If I’m a little high, I lower the nose slightly and gradually correct. As I approach the glide path, I take that slight correction out. The jet may gain a couple of knots or so, but once I remove the slight correction, the jet will tend to correct back to approach speed. If you get a little low, again, slight correction along with a touch of power and that's it. With speed corrections, remember your target power for approach. If you get slow, nudge the power and give it a few secs. If it doesn't respond, give it another nudge. The key here is small corrections, remember what you put in so you can take it out after correcting. Some guys use throttle knob width and half knob width for throttle adjustments. I basically us my wrist to wiggle in adjustments. Laterally, again you want to make small corrections and allow the jet to correct smoothly and gently back to center line. Again, the least amount correction you put in, the least amount you have to take out. The reason I don't like pitch and power anymore is due to jet performance. In jet aircraft, everything lags. If you got low and added power, you would be low and fast before you corrected. In prop aircraft, pitch and power works great. Some props will give you instantaneous lift effect over the wing. In jet aircraft, it's opposite unless you are flying a blown flap jet like the C-17. Like I stated before, we use target fuel flows and N1 settings to get into a baseline for approach speeds. A good technique is to put the weather down to minimums and hand fly the approach. This lets you practice small corrections and see how easily large corrections throws you off. A well trimmed aircraft will naturally seek approach pitch and speed. Letting the autopilot fly for you initially allows you to calibrate your aim point. You want to drive the aircraft towards the captain bars (1000ft down). You want to be on glide path, speed, trimmed for approach and stable. When properly trimmed, your hands are relaxed on the yoke and throttles. You should only make inputs here and there, because a properly trimmed aircraft will fly itself down. In the IXEG 737, I use the 20ft callout for my flare point and power pull. The flare is only a 2 to 3 degree pitch change in the majority of jet aircraft. Just enough to diminish the sink rate. A text book touchdown is a little firm and occurs no less than REF-5 1000 to 1500 feet down. But Rick, what about my greaser? Greasers should be the last thing on your mind. Greasers are long forgotten while egressing the aircraft with your passengers after an over run. I’ve had guys struggle and get aggressive on approach, get lucky and put it down 1000ft down with a greaser. I still give them a U for landing because the landing is an equation comprising of the approach. You want to become consistent with text book landings before worrying about greasers. If someone puts it down firm, but with text book data, I rate it a great landing. Short, wet runways with marginal weather and low vis will make a believer out of you. Once you are consistent with text book landings, you will naturally began to finesse the flare and power pull to get nice touch downs 1000 to 1500ft down. If you fly with me, I’ll send you around when you exceed the 2000ft down point. These are just some tips to assist those who may some minor issues landing. Being high, unstable, fast and off center line will definitely throw off your landings. Take a look at the landing criteria to judge your own landings. Rick

-

Some body please post nvidia settings to reduce all jaggies

-

I only mentioned it because you mentioned IAS and IAS speed loss. I can say it also depends on your altitude you are climbing to. I've flown light to heavy jets and this is the typical behavior i've seen in regard to climb performance. In regards to optimum, I have always been in operations where you climb to 2000ft above optimum. If step climbing, I hang out till 2000ft below and repeat the process. If doing a constant cruise operation, again, I plan 2000ft above optimum. In these cases, I fly the recommended climb speeds and don't stray too far from it even if in a hurry. I've watched guys climb at too fast of a climb speed and couldn't make it until they reduced speed. On average when near optimum and above it, I see climb rates of 500 to 800 feet per minute. When climbing up to the aircraft's service ceiling, its about 300 feet per minute. When I see these type climb rates, I know i'm in the optimum altitude range and approaching the aircraft's performance limits. As you know, you don't want to be below the 500 feet per minute mark for ATC reasons. Here's a good real world operating tip. When climbing in mach in close to optimum, the plane tends to get pitchy when in VNAV or FLCH. When the plane starts to get loose in pitch, we select vert speed to settle it down. When in vert speed, you work the vert speed to maintain your climb speed. You can get in trouble really quick if you let the plane pitch too much. If you get behind the thrust curve, it can take a long time to get back on speed and climbing again. Plus the pitching gets aggressive and leads to overspeed or stalling. If the 737 is climbing correctly, these are good rules of thumbs to fly by.

-

Another thing that can also hinder your climb is climbing with indicated airspeed instead of switching over to mach. The higher you fly, the faster TAS you need for a given IAS. Once you climb in mach, the TAS decreases. Most changer overs occur some where between 27 to 29 thousand when recommended IAS climb speed intersects recommended mach climb speed

-

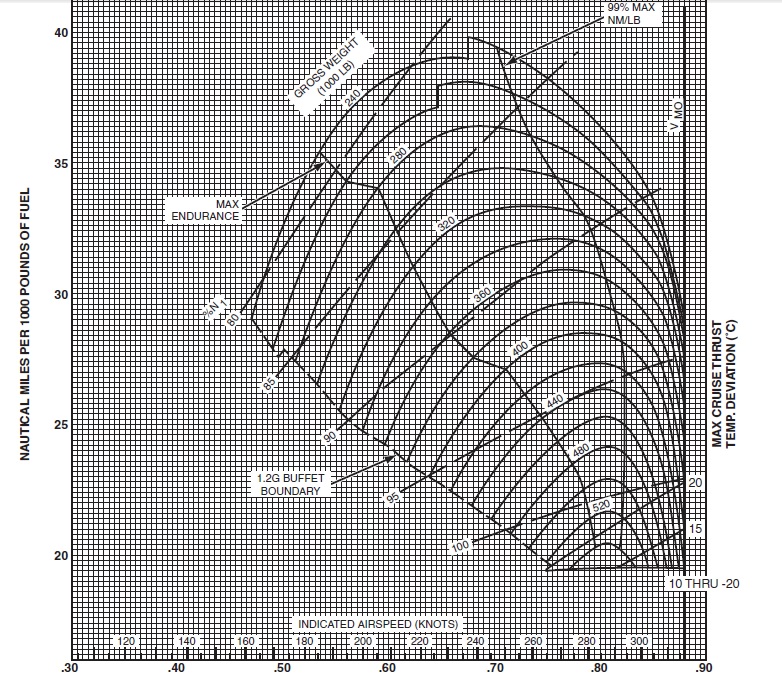

Now you are talking my language lol. This takes me back to the old days of flying when you really had to know the performance of the aircraft and use your performance manual to squeeze every ounce of efficiency out of the aircraft. When I first started flying, my first jet was the heavy C-141B. The performance manual was thick and had a slew of pages of spec range charts. The flight engineer would work the charts and pass you climb and cruise data. You would climb 2000ft above optimum and stay there until 2000ft below optimum and step climb to stay in the sweet spot. Some times climbing wasn't always the answer. There were times when I have climbed, and decided to go back down due to winds and positive temperature deviations. At times you would work the HF radios and airline common freqs to get an idea of what the winds were at various altitudes. I've been in some fuel situations where the weather brief and wind charts were way off, and you had to make quick decisions. You had to consider climb capability, fuel burned during climbs, winds and maybe slowing to fly the top of the curve(100% max range in the spec range charts). We did fuel calculations once per hour and compared the numbers against the flightplan to see your fuel trend. If negative trends are caught early, you can change things and make a difference. In the KC10, you did the same thing. We had extra benefits with extra fuel tanks. The FWD, CNTR and AFT tanks made it possible to adjust CG inflight. Once at cruise, you move the CG to the aft limit of 29%. The tail heavy CG made the horizontal stab streamline, reducing drag. We called this making fuel because the projected landing fuel on the flightplan would increase by 5,000 pounds or more. In rare cases in certain parts of the world, we would file for a block altitude, set cruise power at optimum and cruise climb. Now days its all computerized and dispatch. In the Gulfstreams, I have a FMS what if page in the perf pages. I can set cruise speed or altitudes and it will display actual perf against what if perf for fuel cost. The plane uses a mixture of downlink winds/temp and actual winds/temp for the calculation. Most airline guys have flight following dispatch that monitors weather and performance, and will refile updating more efficient routes. As you stated earlier, winglets also depend on the operation. Winglets and a aux fuel system was added to the C-32s(757). Unfortunately, the small fleet and marginal gains led to the winglets not being cost effective. For some nostalgia for all, I attached a DC10 spec range chart example. We used to work these charts to death lol. Amazingly, .825 was our standard long range cruise speed.

-

There we have it, right on the money

-

Below are some numbers for descent rates attainable and decel timing for a 737NG BBJ. Clean speed brakes speed brakes modded wing 0.78M / 280 knots 2200 fpm 2600 fpm 3100 fpm 250 knots 1700 fpm 1900 fpm 2300 fpm VREF 40 + 70 1100 fpm 1200 fpm 1400 fpm Losing airspeed can be difficult and may require a level flight segment. For planning purposes, it requires approximately 25 seconds and 2 NM to decelerate from 280 to 250 knots in level flight without speedbrakes. It requires an additional 35 seconds and 3 NM to decelerate to flaps up maneuvering speed at average gross weights. Using speedbrakes to aid in deceleration reduces these times and distances by approximately 50%. So in the BBJ, it takes roughly 1 minute and 5NM to go from 280 to flaps up maneuver speed. Think its a close enough reference or guide of how a 737-300 may perform? its about the same length, but does have a longer wing(117 vs 94).

-

Anytime, this is what real world guys should do to help the community and developers get as real as can be

-

merelles and mike, you bring up some good points. So, amazingly my training started with jets from the start. I had no flight experience at all except from flight sim. The training was vigorous and many washed out due to the fast and furious training profile. If you couldn't get basic flying concepts and twin engine jet operation at the same time, you were done. So this guy I flew C141Bs with invited me over to ride with him in a single engine piper type aircraft. I had no experience with prop aircraft and the extra 2 engine levers were intimidating. After some quick explanation during the climb, he gave me the aircraft. Immediately I knew flightsim was wrong because the controls were firm and rigid like the jets I flew. The FSX prop aircraft were super sensitive and twitchy. This aircraft had a heavy feel to it from the air loads. I found myself constantly trimming like in a jet aircraft. In jet aircraft, I find myself trimming every 3 to 5 knot change, pitch change, flap configuration change and power change. In FSX, you rarely trim unless holding altitude or trimming for glide path. I did notice that the plane was more responsive to gusts and wind change while jets had more delay and stability. Aircraft control felt normal though the prop sound change from the gust was unsettling. Engine controls were a different story. All of the precautions around the lever settings made me nervous, last thing I wanted to do was blow the engine. He took the aircraft to demo the pattern and described these different throttle settings around the pattern. He performed a touch n go and gave me the aircraft. Since things were slower, I was able to fly a squared pattern instead of the race track pattern at 180kts. Power settings were strange because I wanted to revert back to setting the throttle to maintain my desired speed. The landing was interesting. I wanted to flare higher due to my normal flare picture, but felt him add forward press to keep the sink coming. At flare, I set a pitch and let it come down as i would a jet. He laughed and said you have to hold it off, very counter intuitive. The second touch n go, I held it off, but felt him add a touch more back pressure. The third time was a charm and I couldn't believe the amount of back pressure needed to hold it off. The back pressure was almost the amount I use during rotation in a jet. Since that time I've flown props and have become very comfortable with them. I've yet to get a checkout in one. I know attempting to fly a prop is a bit scary with all of the engine precautions. Without having a person in the prop with me during the first time, I'm sure I'd risk killing myself. A friend and I wanted to go up during heavy crosswinds since I do it all the time in jet aircraft. After the first circuit in that prop and heavy gusty crosswinds, we quickly called it quits. Needless to say, it didn't feel right and we scared ourselves. Overload of senses can freeze you up as you said. I had this boom operator who was a private pilot. I once illegally let him in the right seat while we were in the Baghdad 500 flying the refueling track for hours. I figure, i'm a instructor pilot, why not. I clicked off the autopilot and had him follow the flight director to maintain the track. He fell into the ol focus on one thing trick. He could maintain heading, but not the altitude. He could maintain altitude, but not the heading. I had to take it from him a few times before he was able to settle down and fly a half decent pattern. I then clicked off the auto throttles and it ruined his world adding speed to his crosscheck. Just as you guys described, I think he fell victim to the overload though he was a private pilot. Things happen quickly in a GA aircraft. He would put in too much input, the plane would delay and suddenly respond and want to keep responding. I had to teach him to put in small inputs, allow the jet to respond and anticipate taking it out. He was getting into PIO too easy, plus he was shocked at how responsive to inputs this heavy jet was. You could fly with your finger tips. Speed control caught him off guard. I had to teach him to use the wrist wiggle technique to make small thrust adjustment. He didn't realize how long it took the jet to respond to thrust changes. A new guy can get in trouble by adding too much or reducing too much power. The DC10 was the first jet I flew that had quiet engines. You only hear the engines right after light off with this deep whooing sound before going silent at idle. Also going above 90%, that deep groan from the fans could be heard. During taxi, you don't hear them. The first indication that you are using too much thrust during taxi is the takeoff warning horn.

-

Good question, for the most part, airline guys usually stay with a type until converting to another type. If the type covers a range like the 757/767 or E175/195(common type or related), you could land in a 757 and run to another gate to fly a 767. FEDEX tried this with the MD10 and DC10, but the pilot union forced a different type, pay related. In the corporate world, it's not uncommon for a company to have a G450, G550 and G5 with pilots qualified in all three. The G5 allows G550 differences which allows 450 differences. The 550 has the same planview avionics as the 450. If G550 qualed, you can do computer based training for the 450. In a NetJets operation, you could possibly fly a G5 to Ireland and swap to a G450 and fly to the UK. Pick up a G550 the next day heading back to Ireland and fly the G5 home. It's painful enough getting permission to do common type or related with different type certs. I can imagine the pain if an operator requested permission for multi qual in different types. I see this alot with test pilots and certain units in the Air force. Test pilots would crazily jump around in different aircraft. There was a unit where you would be qualed in the G3, G5 and C-9(DC-9). Painful because of the checkrides in different type every 6 months. Some how, the G3 was considered same type as the G5, which FAA won't allow. Gulfstream tried to certify the G650 under the G5 series, but the FAA forced them to seek a new type cert. Gulfstream tried to sell it to the FAA as having the same honeywell system as the 550 and 450, but the FAA didn't buy off on it.

-

You hit the nail right on the head, lol. It's all in aircraft design. I'm glad he listened lol. That G5/550 has a big wing and you imagine it feels every little bump of turbulence you hit. It's so overpowered that you pitch for REF minus 20 for terrain/windshear escape maneuvers. The most interesting wing i've flown was on the DC-10-30. It's definitely a highspeed/low lift wing. It had zero angle of incidence and you can go from the East to the West coast of the US if you never rotated. You forced the plane to fly through angle of attack and it lifted off passing 10 degrees nose high 1000ft down. At typical weights, you rotated up to 20 to 22 degrees nose high for V2+10. Rotate and approach speeds were pretty high. It had a max speed of 350/.88 and had been dive tested to .95 with no negative control effects. The slats were critical for slow speed flight, most notable in the AA crash from engine loss during takeoff. The approach speeds for a no slat and full flaps landing are significantly higher than landing with slats and no flaps. That big sexy girl had a long cruise speed of .825. I've only been passed by two jets during my 9 years flying it, a 747 and MD11. She had a wide weight range and behaved like 3 different types of aircraft. There was the heavy weight, medium weight and light weight aircraft. At speeds up to 190kts, the heavy jet took a good pull back on the yoke for rotation. She was slow to respond to speed and power changes, but was responsive to control input. This was more noticeable during receiver air refueling in the KC10. You had to pull the power and flare earlier due to the inertia and momentum. The medium weight jet behaved like most jets. The light weight jet was like a sports car and very responsive to speed and power changes.You had to leave the power in longer and flare later because she would slow quickly. You can imagine how the different weights could throw off your landings. I typically used the 10% of your gross weight technique to stay consistent. 10% of 400K plus 23 = 63% on the N1s for normal landing flaps approach speed and 10% of 400K = 40ft call out for starting power pull and flare. At typical landing weights(380K), threshold crossing speed was 147. The ground spoilers would go to the 2/3 position at wheel spin up. This would actually cause the nose to rise. You had to push forward and fly the nose down to the runway. At nose wheel contact, the spoilers went to full and the ground shift mechanism would allow (#2) engines to go beyond reverse idle. As you can tell I loved this jet and was the most enjoyable to fly with it's perfect mix of hand flying and automation. I brag about her often, but it's awesome that developers like you guys are at the point that you could simulate the things i've mentioned in sims. It's a shame FSX used cookie cutter modeling forcing developers to find work arounds. Keep up the great work Morten!!!

-

You make an interesting point. This post wasn't designed to pit the differing opinions against each other, but to take an in-depth analysis. I say flying airplanes is 90% procedure and 10% feel. In type training, you spend all of your time on procedure. Automation, normal and emergency procedures. The first sim you will do some stalls and steep turns for feel and recognition, but the rest is procedure based. Lets look at critical emergency procedures. These procedures are designed in a way that they will come naturally. The hope is that naturally you will revert back to those procedures with little thought. Believe it or not, it's been proven to easily shut down the wrong engine or apply the wrong procedures with engine failure to the wrong engine. In the AirForce, we taught guys to just step on the ball. That's much easier than looking down and trying to decipher which engine. That becomes a natural inherent procedure. If you have a guy/gal who flies the sim proceduraly correct, chances are he could possibly do it in the real aircraft. We learn in flying that feel and sensory are not everything and can be deceiving. Lets look at upset recovery. In recurrents, the flying pilot will relax his hands in his lap and close his eyes. The non flying pilot takes the aircraft and puts it in an unusual attitude and gives the jet back. The flying pilot then open his eyes, analyze the instruments and apply the appropriate procedure for recovery. That exercise teaches you that you can't rely on seat of pants senses to correct the problem. If a guy is procedurally sound for a particular aircraft, he could probably get by with normal things. I had flown flight sim for years and during flight training, my instructors were shocked.They would constantly ask if i had flight flight experience and my answer would be no. Basic flying and navigation was easy for me. It was the procedures I had to spend time learning. My instructors considered me a natural, but that was all due to flight sim flying.

-

Yes Sir!, I made that post almost 2 years ago and now xplane is my go to. You guys have made an excellent representation with the 737. I flew the other 737 in FSX and I immediately contacted them about the ground effect and approach pitch it had. Finally they posted the unreliable airspeed chart, which carries extra speed for safety. After that they adjusted it to the real approach numbers but it still has a tad much ground effect. Guys were constantly posting how slippery and realistic the ground effect was lol. Your model along with xplanes ground effect is perfect. I probably fly the most slippery jet out there. With 41,300 pounds fuel, the GV has a 6500 mile range. At the 50ft call out, you have to go to idle and start a 2 degree flare at the 20ft call out. This puts you down around 1000ft. Any extra speed or more than 2 degrees puts you 2000ft down, now that's slippery. The G550 has the same tube and wings, but cockpit upgrade with the Honeywell plane view system. By adding vortex generators above the cockpit , extending vortex generators on top of the wing up to the winglets, adding a 2 piece flat panel outflow valve and making the trailing edge of the flaps and inboard wing section 2 inches thick...they extended the range an extra 250 miles(6750). In the G550, you have to go to idle at 100ft. The 737 has used the same tube for years and isn't as slippery as the other guys claim it to be. I'm excited to see what other aircraft you guys will pursue.

-

lol, but I've also given to the points needed for success.

-

I think it's more driven by those who have that dream of flying real world, but never had the opportunity to do so. What's interesting is when you actually take a close analysis to judge if it's actually possible. This question sims to come up a lot. This one and max speed below 10,000ft

-

I've had some response here at the IXEG forums and i've decided to post information from a real world standpoint. Below is a post I've made before that discusses if the average simmer could actually fly a real world jet. Check it out and post your thoughts. Rick THE TOPIC Ladies and gents, there have been some past discussions about a flight simmers ability to pilot a real world aircraft. The most recent topic comprised of flying a 737NG. There were plenty posts about the probability with varying perspectives. To have a good view point, one must understand what goes into flying a real world aircraft. For the most part, most of us are very familiar with the flight sim process. Some of us actually have real world experience in the flying biz. With that in mind, I think it's better to take a close in depth look at the possibility and how one would go about accomplishing the task. WHY Someone asked in an earlier post, "Why would a real world pilot even bother with FSX". Well for me, I learned a lot about flying from flight sim and the community. I was a flightsim addict when I was young. My dream of flight started with flightsim and it made the process easy. I've been flying for about 17 years now and I think flightsim paved the way by planting the seed. I know flying isn't for everyone. Some who are interested may never get the opportunity. It's in flight sim where many will get to experience flight. I returned to flight sim and the community to give back. If I can pass on experience or answer questions, I’m happy. I give advice to those who want to sim realistically. I've also been a part of a few beta test teams where I aimed to test flight dynamics against performance manuals and my own experience. This is why I stay active in the community. THE SET UP In this topic we will focus on an experienced flight simmer that uses add-on aircraft and flies them in a realistic manner. We can base it on a 737NG, but use jet aircraft in general. Here is the mind set. Most modern jet aircraft are the same in general. Systems are very similar. They are certified by the same requirements. They are typically flown the same. Some terms may differ by aircraft. Let’s look at the system that controls whether aircraft is in the ground or air mode. Lockheed called the components touch down switches (sws). Micky D called them ground sensing mechanisms. Some refer to them as squat switches. Gulfstream has called them nut cracker sys/sws and moved on to call them weight on wheel sys/WOW sys. Either way they perform the same function in the same manner. Autopilots, flight directors, auto-throttles and modes are the same throughout aircraft. What really changes between the aircraft are the flying procedures. Type ratings mainly focus on the procedures of that particular aircraft based on characteristics and capability. You have to know the automation/FMS procedure as well as the manual procedures when becoming qualified. This is what makes going from jet to jet easy. It also makes it easy for negative transfer. This is when you apply procedures from one aircraft to another. It's easy to do since the systems are similar. In reality, flying is all about habit patterns through repetition. We will look at the pros, cons and pitfalls of flightsim vs RW. THE SCENARIO Let’s say for some reason the walking dead have invaded your town and you need to get your family to safety. Or maybe Mayans were a tad bit off on the date and now you want to fly it out. So you happen to come across a 737BBJ or similar Boeing, you choose (no airbus). Someone has left the stairs down and the door is open. You scream "Get your @#%^& on!" in your Sam Jackson voice. If you are lucky, the jet is powered up. In this case it's not. POWER UP Above we mentioned how most jets are similar. There is usually an electrical control panel in the cockpit. The question would be, can an experienced simmer figure out how to power up the jet. In my experience, powering up a jet is straight forward and simple. Most jets are self sustaining, meaning you can operate the jet without any ground equipment. This can get difficult for the simmer. When I was flying heavies, there were plenty circuit breakers that would be pulled after flight. They were in the cockpit. This prevents some equipment from turning on while the aircraft is powered up. Radar altimeters, standby ADI, and probe heat were some of these items. Mx would install colored collars for quick identification of these breakers. Even though the DC10 had a ground service bus that only powered up the cabin, the breakers were pulled and full power would be applied. Now on the other side, in the Gulfstreams that I fly, things are all ways left on and no breakers are pulled. Even the radio, cabin, FMS, and SAT TV masters are left on. Some operators turn them off and some don't depending on the Mx costs they've experienced. I have found situations where the CDU and Display Units are dimmed to save on wear and tear. The Display screens are also turned off. Would the simmer be aware of these situations? Would he know to check breakers and sws? Most sim aircraft don't simulate these situations, but some do. An experienced simmer may be able to power up the aircraft. As I said it's straight forward. Due to add-ons, he may know that he needs the APU. He would also know that he has to turn the batteries on. A glance around the cockpit and he would surely find these items. In the real world, I all ways perform a radio check on VHF1 and APU/ENG fire test prior to starting the APU. In this case, he may not know and he doesn't need it. It would be nice to know that the APU fire sys works, but i haven't ever had an APU fire. Now in the aircraft I’ve flown, there were always flight pubs and aircraft pubs on board. In our jets we have laminated checklist and SOP briefing cards that are left in a pedestal slot. In the cabinets, we have the full set of flight and aircraft pubs. Our aircraft are all ways worldwide ready to go. I think the simmer would be able to power up the aircraft. The aircraft pubs greatly increase his chances if he finds/chooses to use them. PREFLIGHT The simmer wouldn't have an idea about the full preflight. Some operators have forms that are used for checking the status of the aircraft. You can check the Mx history in them. He would probably know that some items need to be turned on. There are also items that need to be removed. Once again, some sim aircraft simulate removing pins, and covers. The nice thing is that removable items are tagged with red streamers that scream, remove before flight in white. Some items are just red. The preflight turns on/test systems and prepare them for flight. Some things are critical like chocks, parking brake, and gear pins. These 3 will get you in trouble fast. Systems are easy to turn on. Most systems are grouped together and are clearly labeled. Chances are, they are left in the on position. He would have to know the things that are critical to flight. Some jets have hydraulic switches, trim switches, anti-skid, flight control sws etc. From jet to jet, some are always left on and some are turned off after flight. Modern aircraft are also designed in a way that you could easily tell if something is out a place. There are usually four colors that you will find. They are green, blue, yellow and red. We all know red is associated with something wrong. I find that yellow is usually associated with a switch in the off position. Blue is usually an advisory. Blue may tell you that you have selected something on. For example, in the G550, the APU master sws reads on in blue when it’s in the on position. It’s just a reminder that you turned it on and you have to select it off. There will also be a blue cas message that reads APU MASTER. Would the simmer know this, maybe? But he could easy look around and check for yellow and red lights. Most cockpits are designed in a way that when the aircraft is fully configured for flight, warn/caution lights are out and no messages are displayed. FMS The FMS and IRS systems can be interesting. Setting position can be a challenge. Most add-ons simulate this very well. There are some pitfalls. Both systems will be easy to find. Most INS systems will perform a self test on power up. You should turn them on first. Most systems will not accept position until the test is complete. They would have to be in the align or nav mode in order to accept position. The only difference between align and nav is that align will hold and keep the align state. In nav, the INS will start to drift as soon as the alignment is complete. If you load the pos before the 10 to 15 second self test is complete, you wouldn't notice it. They will start the countdown/alignment process. At the last state, the align lights will start flashing at you. The simmer could become confused if this was the case in the type aircraft he jumped in. He can fall into a cycle of this as he reset them. For the most part the FMS system is pretty easy. On power up, most will usually default to the NAV IDENT page. Software version, time, date, and active database will be displayed. You can select pos init from this page. The smart guy would load the GPS position. Another pitfall is the pos format. If you have to manually enter the position, it can confuse you. In older systems, you would load lat first and then long. In the Honeywell, you have to type the lat and long together, but it needs to be in the correct format. You can follow the last pos format and load it and you have a chance. If the jet was towed, you would still be within a mile you hope. The universal is more difficult. There is a specific page and way you have to load it. For the most part, the FMS will walk you through the order of what’s needed. It prompts you through the rest. The experienced guy would have no issues unless he is on an airbus. He could go low level VFR, or direct or add a complex route. At minimum, if he can't get the INS up, he can select ATT which will give you basic attitude ref minus the nav capability. He could also use air charts and navigate by nav stations. FUEL If the simmer can work the FMS, he can figure fuel requirements if the FMS is properly perfed. Adding routes can be easy. He may be savvy enough to be complex. He can also go direct or forgo the FMS all together. 15K or more, he can get somewhere. Less than 15K, options are limited. WEIGHT and BALANCE The BOW weight can be tricky. Most FMS systems will keep the last weight entered. Weight and balance is another issue. I doubt that a simmer can calculate weight and balance. If he is lucky, the aircraft will have a canned weight and balance book on the aircraft. Most smaller aircraft will have a chart that’s based on passenger load. The FMS will usually have weight and balance internally requiring only the basic weight and pax/cargo load. Other operators will use a system/program that calculates it for you. Out on the ramp, you may be out of luck. If you have no way to figure out the weight and balance, you are rolling the dice. If the weight in the FMS is close, you still need to know cg information in order to get a trim setting. Only a person with time around the aircraft might have an idea of how the aircraft sits empty and how the cg moves as pax and gas is added. Every jet will be different based on its configuration. The DC10s i flew had a range from 8 to 29 for flight. Empty, it sat 12 to 15. When loaded, the CG moved aft to 25 to 29. Most aircraft are tested to be controllable in an out of balance/trim situation. Here’s some experience for ya. I was flying a Gulfstream from NY to Shannon. During taxi, my CO had an issue trying to reach tower so I took the radios and got the clearance. On line up i performed the ground spoiler test and armed them. I did a quick safety check and pushed throttles up to takeoff power. As we hit 60 the yoke rose to neutral and the co called 80kts, controls free. I came off the tiller, grabbed the yoke and stated pilot’s controls. The CO called V1- Rotate and I added back pressure. The nose didn't lift. I pulled further back and the nose slowly rose as he called V2. I trimmed nose up while adding firm aft pressure. I glanced at the trim and noticed it was just passing into the green. We cleaned up and continued. During taxi, he had been pushing nose down trim instead of the PTT while calling tower (common). Unfortunately that model Gulfstream has no warning for trim being out of the green. It doesn't sound when in motion either. From that point forward i check trim when taking the runway. WALK AROUND Most simmers have rode in an airliner and watched the pilot complete the walk around. Training will teach you the specific items, but most aircraft are the same. Parking brake, gear/door pins, chocks, doors, panels, covers, flight controls and taxi area are the biggies. Other than that it's general condition. It's a 50% chance a simmer would know what to look for. Would he notice if something was missing? What should be open, and what should be closed? A simmer with ramp experience has about an 80% chance. As long as the biggies are covered, he can make it. ENGINE START Engine start is pretty easy. Bigger question is, would they be able to get the stairs up or pulled away from the aircraft. Some aircraft have an alternate way to enter the aircraft from the ground. If he is lucky, the aircraft may have internal retractable stairs. Most exits and doors have instructions near the controls. There are 2 things required for engine starting. We will need electrics and pneumatics. Aircraft these days are very easy to start. A quick scan of the overhead and pedestal will identify start controls and indicators. Most aircraft will have start arming controls along with starter sws and fuel levers. A checklist would be very helpful with configuring for start. Mainly start systems armed, AC packs off, throttles idle, parking brakes and accumulators set/charged and proper pneumatic pressure (30-40PSI). Most simmers could figure this out. Big thing in the old days was fuel scheduling. My past jets required fuel at 15% N2. Now days sophisticated aircraft will introduce fuel and ignition when the FADEC feels it’s appropriate. Last is to know start malfunctions. Rapidly rising EGT, hung starts, no starts, and failure of the start valve to close were the biggies. I can count on both hands the amount of times I’ve had start malfunctions during starts in 17 years of flying. This shows that they are rare. Modern jet engines start without complicated procedures. I think the simmer could handle this very easily. Also most engines require a 5 minute warm up period before takeoff. Finally one would have to reconfigure the panels after starting. We call this the after start flow. Again, the checklist would get you in the right configuration. Key note is that items in the checklist will most likely have SET written next to them. One would have to know the proper settings. TAXI Taxi can get difficult depending on the aircraft. The many times I’ve seen tire marks in places they shouldn’t be around the airport. Let’s take my beloved DC10 for example. You sit 21ft above the ground. The point at which you can see the ground ahead of you was 55ft away. The point at which you could see the ground out the side window was 35ft away. The nose landing gear was 21ft behind you while the mains were 72 feet behind the nose gear. The wings were 165ft 4in from tip to tip and you could not see them from the cockpit due to the sweep. This made the aircraft difficult to taxi. You had to use many references in the cockpit in order to know where your wing tips, main gear, and engines were tracking along the ground. During 90 degree turns, your body would be physically over the grass before you start turning. You used references to imagine nose tire positions during turns. Turns made some uncomfortable. The most common taxi incident was running over taxi lights or putting a main in the mud due to under turning. The guys I know who did this didn’t realize it until they were called by the airport after departing. Would the simmer know these references? Probably not. Taxiing a Gulfstream is too easy, but as you move up in size so does the difficulty. Transitioning from the sim to the real aircraft creates a challenge. Staying on the taxi line and offsetting during turns will be key. Trouble usually starts when maneuvering around obstructions and other aircraft. Performing single pilot ops or having an inexperienced person in the other seat makes things very marginal during taxi. Is it possible? Probably. Also, taxi speed and brake use can be a factor. Too much speed and brakes can overheat things on a long taxi. I’ve heard of guys riding the brakes and tripping the thermal fuses in the rim of the tire. It’s very hard to taxi with flat tires. This is another great time to have that checklist to help set up for takeoff. Proper flap settings are critical. In FSX, most aircraft will get airborne with improper flap settings. In real aircraft, you can easily find yourself with hands full of stick shaker after liftoff. It’s been proven plenty times that aircraft will not fly with improper configurations. TAKEOFF Ahh, takeoffs are the most important/dangerous part of flight. You have to accel from a stand still through stall speed to get airborne with a high power setting. First we have V-speeds. Most simmers understand V-speeds. The takeoff roll itself might surprise an experienced simmer. Takeoffs in the sim can be misleading. Let’s look at this closely. Power application should be standard. One may find it surprising how spool up rates between engines may differ. This could lead to directional control issues initially. This is why it’s good to align the N1s/EPRs before applying power and applying smoothly. Crosswind controls become important. Some aircraft will weathervane easily into the wind and others tend to roll away from the wind like a barrel. This requires proper input to stay aligned and prevent scraping a wing tip or engine pod. New guys tend to zig zag down the runway. One should know that tiller use is discouraged especially above 80kts. Takeoff should be done with the less sensitive rudder pedal steering. Keeping an eye on speed may be a minor issue. Pilot performing the takeoff should have his/her eyes outside until coming inside during the rotation. Our simmer would have to peep inside from time to time which could lead to control issues. It’s so much easier when you have a CO who states those speeds for you. The next sneaky challenge is the rotation itself. Most jets are trimmed for V2. Initially during this 3 to 4 second rotation, the nose is a little sluggish requiring some input. As the nose lifts, you accel past V2 and the nose begins to rise quicker on its own. At V2+10, you will find yourself pushing forward on the yoke to keep the nose from rising. Experienced real world guys are already leading this issue by trimming nose down at some point during the rotation. You don’t find this in add-on aircraft. So imagine our simmer trying this for the first time. He would not be familiar with the stiff yoke. If he rotates late, there will be even more force to overcome. This situation can easily lead to a power on stall. He could panic and over control the aircraft. The next sneaky situation is speed itself. If you are overwhelmed and caught off guard, you could over speed some things. An experienced simmer my know how to use automation to slow things down. Next are configuration changes. You have to be careful when and how you clean up. Most aircraft limit you to 15 degrees of bank during the cleanup. Anytime you are below min maneuver for your existing configuration, you should limit to 15 degrees. Retract too early and you meet the shaker again. One would have to be ready and on top of things after takeoff. You have 5 minutes on takeoff power. The power may switch to climb, but it’s still a lot of thrust churning. This is where the simmer runs into trouble as the engines could care less about speed limits. This is the regime where real world guys over speed things. You have to keep the nose up (pitch and power) to control speed until you can turn on the automation and enter into a good speed mode. Automation will help greatly with slowing things down as long as one knows how to use it properly. CLIMB-CRUISE Climb and cruise is very simple. There’s not much too it. The biggest threats are over speeding, no/loss of cabin pressure and running out of gas. These are very avoidable if the simmer is good with systems and the FMS. One other threat is weather. Manually loaded flight plans are not winded. This could cause some time and fuel miscalculations. One could take the actual winds and load them along the flight plan points. Last is weather radar operation. You have to dodge cells. He has to know how to paint cells and use the tilt to get a working idea of a cells make up. Day time is easier but the radar is essential when flying at night or in the clouds. One must also know when to use anti-ice. Most sim guys are sharp on these rules. ARRIVAL-APPROACH The arrival isn’t difficult, but it’s the key to a good approach. The simmer would need to plan out his arrival. Most guys are familiar with the FMS and know how to pull info for descent estimation. Late descents lead to fast and rushed approaches. From the old school days I learned to use the 4 times your altitude to lose rule. For example, I have to lose 30,000ft to reach the IAF/FAF altitude. 4 x 30 = 120NM to make it. In this example, I need to start down no later than 120NM from the IAF. This has worked well in all the types of aircraft I’ve flown with idle descent. It also accounts for time to slow to 250 before passing 10,000ft. There are 2 ways to arrive. You have Instrument app or VFR pattern entry. The Instrument app is easy and can be accomplished using the FMS or NAV radios. The FMS is easy to setup and the ILS is easier. The simmer would be very familiar with approach procedures. Minimums/MDA settings will be more of a factor during approaches at night or in the weather. Big thing is knowing when to slow and configure. What flaps to use and when to use them. Flap selections are either driven by speed along a certain leg, distance from the field, or position along the approach. It all depends on the type of approach you are flying. Let’s look at the 737 for example. On initial setup/vectoring for a ILS/FMS approach, you want to be at flaps 1. Approaching intercept, you want flaps 5. At glide slope/path alive, gear down and flaps 15. When the path is a dot above, select landing flaps. The VFR pattern can be just a bit more challenging. You would have to have the proper displacement and altitude as you enter downwind. You would prefer to have the runway on your side of the cockpit. VFR patterns in most jet aircraft are race track patterned. The turns from upwind to downwind and from downwind to final are constant. This keeps you in tight and within the airport airspace. In the jets I’ve flown, we fly the pattern at 180kts. The experienced simmer may not have the practical knowledge for the particular aircraft he may be flying. This is where the challenge resides. I’ve watched real world guys fly very good vectored instrument approaches and fly very sloppy circling and VFR pattern work. It’s very easy to become unstable in the VFR pattern. Misjudged displacement and rapid descents from downwind usually leads to excessive maneuvering and diving during short final. The flight sim makes it difficult to simulate unless you have Track IR. This is how I fly my patterns real world and I’ve used this in every jet I’ve flown. Enter downwind at pattern altitude, no less than 1000 to 1200 feet agl. I have a calibrated eye for displacement but you want to have 1 to 2 miles of displacement. After flying patterns for a while, you tend to know when you are in too tight or to slung out with a glance. You want to be at 180kts with maneuvering/go-around flaps. Turn off the FD and set the heading bug to the runway heading. The FD can be distracting, but the heading bug will give a good idea of how you are tracking in ref with the runway heading. Having the ILS tuned and displayed is a good idea if available even though ILS and visual glide paths may not match at some fields. Keeping an eye on displacement will help you gauge under/over shooting winds. Modern aircraft will display wind direction/drift on the MFD or in the FMS. When you are abeam the threshold, drop the gear. When the end of the runway meets your shoulder at a 45 degree angle, start your turn, descend up to 500fpm depending from your pattern altitude, and start slowing towards your approach speed. Depending on the winds, you may have to shallow or increase your bank angle. As you move through base during the turn, select landing flaps and pick up the visual glide path. At this point you can easily adjust your sink rate to get on the path. Without glide path indicators, you have to eye it by using the 3 to 1 rule (3nm for every 1,000ft). This is why the ILS is nice to have for reference without visual guidance. Aim to roll out on centerline and avoid angling towards the runway. If done correctly, you should be in the slot/good position for landing. LANDING The landing has some pit falls for the simmer. One would be crosswind controls. I feel that FSX fails to effectively simulate an aircraft’s behavior during crosswinds. I am a wing low guy. I like to apply my crosswind controls at short final. I get a good feel of what’s required instead of waiting till the flare. Another would be sensory overload. I even see this with experienced pilots transitioning a new type. There are a lot of things that go through your mind during landing. New guys get into the “penguins on an iceberg condition”. There are only so many penguins that can fit on the berg until some fall off. As you learn new things, you tend to forget old things. The new guys tend to give up crosswind controls after touchdown, because their minds switch to other things. They forget to use the reversers or to go beyond reverse idle. Some forget to fly the nose to the runway. Firm landings tend to freak new guys out causing them to slam on the brakes and get squirrely in steering. If this can happen to experienced pilots, imagine a guy who has never flown before. He may accomplish these things easily in the sim, but now there are other sensory stimuli he could not get from the sim. Let’s take a look at things he would have to wrestle. Once on final, he should be focused on aim point, glide path, and airspeed. Some guys use N1 settings or a given fuel flow to maintain airspeed. This comes from experience. It’s Easy to set a fuel flow that will get you to a speed instead of jockeying the throttles to get there. Depending on the aircraft, throttle movement would affect pitch. The simmer would not have any of these techniques to assist him. Even in the DC10-30 we used 10% of your gross weight plus 23 for a good N1 setting when landing with flaps 35. While he monitors those, he should be going through the landing in the back of his mind. It would help if he has some knowledge of the flight manual landing procedure. He would be thinking of flare and power pull timing, crosswind controls before and after touch down, getting the reversers unlocked after touch down, flying the nose down, up and aft on the reversers, and when to apply the brakes. When these are second nature, it’s very easy to do. When you are new at it, it can be a task to remember all. On approach he will have to fight for centerline while making small corrections to stay there. This is another reason I’m a wing low guy. It’s Easier to judge my track when my nose is pointed right down the runway. Just keep your inside foot on the centerline and you will get there. As the plane enters ground effect, it may act different. In some, the nose tends to dip while others it may raise. I find flare timing easier when done off the radio altimeter call outs. I picked it up in the DC10 and now its habit. Most aircraft only need about 2 to 3 degrees of pitch change in the flare. Again, some add-on aircraft will not give you a good representation. Most planes you add your flare and hold it till touch down. Pumping the yoke for smoother touch downs after the flare will lead to floating and loss of airspeed. If done correctly, the aircraft will continue to sink on its own. The MD80 gets floaty in ground effect and will climb if you pitch a little higher than required. The G5/550 is notorious for this also. It approaches at -.5 degrees and will float if you get the nose higher than 2 degrees. We pull to idle at 50ft in the 5 and 100ft in the 550 because of the slipperiness. We raise the nose a couple of degrees at 20 feet and she settles nicely. TOUCH DOWN-ROLL OUT Once on the ground, the game isn’t over. Flight sim is missing a lot of aircraft characteristics. Let’s look at crosswind controls. When the mains hit the ground, the ground spoilers pop up. On most aircraft, the roll spoilers become ground spoilers. This requires immediate added upwind input. The aircraft is still flying after touch down and will tend to roll away from the wind and drift. Some aircraft like the gulfstreams will weathervane into the wind. This has happened to me with new guys and I’ve had to add aileron or push on the rudder when guys didn’t use enough or totally relaxed crosswind controls after touch down. This can get the simmer into trouble very quickly. Where ever your nose is pointed on touch down, that’s exactly where she wants to go. I’ve been scared enough that I’ve tapped the brake as a new guy broke my comfort zone while drifting on a touch n go. You could scrape an engine or depart the runway without crosswind controls. In flight sim, this effect is missing. The ground spoilers will also affect pitch control. On the DC10 the nose will tend to rise as spoilers deploy. You had to prevent this and fly the nose to the ground. I’ve watched many new guys yanking at the reversers in confusion wonder why the levers won’t all go past reverse idle. The reverse idle interlock for #2 will not release until the nose strut compress and put the aircraft in ground mode. The Gulfstream nose will fall rapidly as the spoilers deploy requiring a quick pull on the yoke to prevent the nose from slamming. One would have to know when to use the tiller. Use it higher than 80 kts and you can get into trouble. Even at 80kts, my hand is resting on the tiller not using it. The simmer would have to know when to use the brakes. Yes, you can apply the brakes after touch down but it would be a shame to have a fire after successfully landing the plane. After touch down, I usually use just slight pressure to ensure operation and then release. I stay off the brakes until 80 kts unless I need to stop rather quickly. When braking, you apply even pressure till moderate deceleration is felt. The simmer could get into trouble while braking and using rudder. I find that new guys tend to sway and zig zag during this time. Usually it’s crosswind rudder that causes them to apply more pressure on one brake than the other. This causes the guy to modulate the rudder leading to oscillation. Too much of this and off we go for a ride off the runway. It’s not uncommon to have hotter brakes on one side during crosswinds. Thrust reverse use is pretty simple. On some aircraft, one reverser may open quicker than the other or they may spool at different rates. This could lead to control issues if it’s not quickly countered or stowed. For the most part that’s it. SUMMERY-CONCLUSION We talked through what an experienced flight simmer might face when it comes to operating a real world aircraft. Some items such as weight and balance would be a big issue. It’s difficult to pick up weight and balance if you are not familiar with it. I remember my first attempt at a manual weight and balance form. It was no fun. Once I tried it a couple of times, it became easier. If my computerized version was to fail, I could knock one out by hand very easily. As I mentioned before, it’s a crap shoot. If the simmer has flown his aircraft in a realistic manner, he would have a chance. It’s an uphill battle but it’s possible and the odds would be against him. As long as there weren’t any failures or aircraft issues, he may be able to pull it off. Add 2 experienced simmers and the probability increase greatly. Rick

-

Thanks all, when IXEG create excellent realistic products, it's great to have some real world info to go along with it. I may start posting here more often.

-

As many of you know there are plenty of things to remember and many of ways to operate in the real world. I will pass on some of the tips I use real world that should help in the sim world also. One of the biggest concerns when flying passengers is passenger comfort. It's even more important in the corporate world that I operate in. From time to time I find myself riding as a passenger when attending recurrent sims and when picking up/dropping off aircraft. One of the most noticeable things when riding as a passenger is sudden or aggressive pitch changes. This happens for various reasons, but here are some tips to minimize the occurrences. When initiating climbs, it's a good idea to start in vertical speed. Select vert speed and smoothly dial it up until the engines reach max power. Once there, select FLCH and the passengers will not notice at all. If you select FLCH first, the engines will surge forward, and then the nose will pitch quickly to maintain the current speed. The Gulfstreams I fly have the ability to decide the amount of thrust to use based on altitude changes 6,000ft or less, but it still can get aggressive. Some guys like to set 200 to 300 feet per minute in the first few seconds and last few seconds of the altitude change. I prefer a smooth increase instead of wasting free brain cells milking the vert wheel. In the real world, FLCH gets pitchy after mach change over, but no worries in the sim. When using FLCH when climbing above change over, I watch it like a hawk. As soon as the plane starts a move, I hit the vert speed button to lock it in. Once the airspeed settles/recovers, I max out the engines and re-engage FLCH. This happens because of temperature inversions and wind changes as you climb. This can easily cause a instantaneous change on the speed indicator causing the plane to quickly pitch to adjust. If you are paying attention, you will see the speed change and hit vert speed before it pitches. When the jet is heavy, it lags a little and makes FLCH less pitchy. Another good tip is to use vert speed when light weight if you are clear of obstacles. 2000fpm works well. This technique slows things down and makes the jet more manageable. If you are climbing at 4000 to 5000fpm, the jet will make an aggressive zero g maneuver at level off. It's much easier to use vert speed in this case. When I would return back to base after training missions back when I flew KC-10s, we would do about an hour of transition and pattern work. We would get back at about 380,000 pounds compared to the max 590,000 pounds. Newbies would perform an autopilot go around up to 2000ft. At 380K and 3 engines churning out 52,500 pounds of thrust each, 2000ft comes very fast. The look on their faces when the plane would aggressively pitch to capture and every now and then blow past the altitude, was priceless. I taught them that after you hit TOGA and the plane gets going, you needed to quickly vert speed and back it off. If you hit vert speed too late, you would ruin the capture mode and blow past the altitude for sure. Those were some fun times. Another good tip is speed brake use. I hear plenty sim experts shade people for speed brake use and I think it's rubbish. They were put on the plane for a reason. I also spend a lot of time operating on the NE coast of the USA and we get slam dunked into airports all the time. They keep you up longer and only step you down a few thousand feet at a time. There isn't a descend VIA, it's only constant crossing restrictions on the way down. I hardly ever get to use VNAV on descents. What you find is that you have to use speed brakes and use them early! Even in the real world i see people get so far behind and rushed because they were taught not to use the brakes. It's quite common to ride the brakes on the river visual to 19 at KDCA. There are two tricks to speed brake use. 1. The earlier you use them, the less amount you will need. SA is everything. 2. Speed brake use is like slipping out and back into bed with your significant other sleeping. You ease them out nice and slowly. Once you are done, you ease them in slowly. In some cases, you have to ride the brakes until you are ready to trade them for flaps. You work in flaps, and then ease in the brakes. I'm sure if you could descend when ever you want, you wouldn't need them, but welcome to the real world. When operating in areas with close multiple airports with departure and arrival corridors, it gets interesting. I like the 3 or 4 times your altitude to lose technique. So if i have 10,000ft to lose to be at 2000ft 10 miles from the airport: 3 X 10 = start descent by 30 miles from the field. 4 times your altitude to lose works well also because it gives you more time to slow prior to 10,000ft. If you are at or past this point and have yet to descend, you will need some brakes. Guys will say that the brakes are loud and rumble, I guess they have never sat aft of the wings on an airliner. For slowing, I like 12 at 12 or 13 at 13. Basically set 1300 fpm at 13,000ft to reach 250kts by 10,000ft. This has worked very well in all the jets I've flown. In most jets, you can only get 1500fpm and maintain 250kts clean. Any higher rate, and you will accelerate. Just in case you didn't catch my 737 techniques in another post, I'll post them again. Keep in mind that these are more aimed at the BBJ, but should work. Aircraft References • Main Gear on your side: NESA Transmitter in lower outboard of window • Main Gear on Opposite side: Lower inboard corner of window • Outboard Side of Engine on your side: Window Handle • Outboard Side of Engine on Opposite side: Glare Shield bend • Wingtip on your side: 2.5 concrete blocks • Nose Gear: Inside of HSI Engine Start (Approximate values) • 2 -- 20% N1 • 4 -- 400 degrees EGT • 6 -- 60% N2 • 6 -- 600 pph FF Before Takeoff (LLLAASSTT Chance) • L-anding Lights (tech: nose wheel light on when cleared for takeoff) • L-adies (sit the FAs down with PA message to the back) • L-ower DU display cleared • A-utothrottle ARM (tech: when cleared for takeoff) • A-utobrakes - RTO • S-trobe lights ON • T-errain (tech: Captain Terrain/FO Weather) • T-CAS (TA/RA) 10,000’ check during climb out (FLAAPS) • F-uel Pumps (Ctr Tank management per alternate operating procedures) • L-anding Lights -- RETRACTED/OFF (consider 18,000’ in high-traffic areas) • A-irspeed -- accelerate to desired climb speed • A-PU -- Off/as desired for shorter flights/EROPS/WX • P-ressurization check (Auto/pressurizing/cabin alt OK) • S-eatbelt (double ding by going off/wait 1 sec/on then auto) Before Descent (AIRBAG) • A-TIS • I-nstall the Approach • R-adio’s -- Tune and ID • B-rief the Approach • A-pproach Checklist • G-o Around Procedures (How will the airplane fly it? HDG SEL, etc.) Planned Descent Point • Timing -- Approx. 10 seconds for every 100’ of altitude to lose • Distance -- Divide HAT by 300’. This is the distance to start descent from the end of the runway. Enroute Descent Path Planning • Build a waypoint 40 NM track distance from the landing runway with 240/10000 inserted for Speed/Altitude. - AND/OR - Use the fix page and put a 40 NM circle around the runway (or FAF) and plan to cross the circle at 240/10000 for a straight-in arrival. • When planning an enroute descent to radar vectors to final it can be difficult to determine how far out you will be vectored and how soon you should begin your descent. Request a descent at a distance that will allow a constant 1500 fpm descent. To determine this descent point: • Load the expected approach using the FMS DEP/ARR page • Load the FAF or OM point/altitude on the descent page at 3R. • You can monitor the V/S as you approach this point. When the V/S approaches 1500 request descent. Even if the descent is not granted immediately, you will have a very good target descent rate when ATC permits the descent. This technique provides a constant descent that mirrors our constant climb to cruise profile. Descent Profile • 3.5:1 (Miles : Altitude) • For every 50 Kts of wind +/- 2 Miles • Losing 10 KIAS Takes 1 NM 10,000’ check during descent (10,000’ AGL for higher field elevations) (FLAAPS) • F-uel Pumps (Ctr Tank management per alternate operating procedures) • L-anding Lights -- EXTENDED/ON (consider 18,000’ in high-traffic areas) • A-irspeed -- decelerate to 250 • A-PU -- On/as desired/WX considerations • P-ressurization -- set for landing field elevation • S-eatbelt (double ding by going on/off/wait 1 sec/on) Cat II/III ILS (ABCD) • A-PU -- On • B-rake Setting • C-at II/III ILS Procedures • A -- Approach Brief • A -- Alert/Decision height callouts • A -- Altimeter bugs (radio and barometric) • D-epart runway plan (How will you taxi to park -- SMGCS?) Before Every Approach • “AAABBCC” • A-TIS • A-pproach loaded in FMS • A-irspeed set in FMS • B-rief • B-rake setting (off, 1/2/3/Max) • C-hecklist • C-onfiguration (flap setting) • “CRAMPS” • C-ourses -- set/verify inbound course on MCP for FP & PM • R-adios -- set/verify correct frequency (ILS/VOR/Tacan/NDB) • A-ltimeters -- set/verify QNH/QFE as appropriate through transition • M-inimums -- set/verify for PF & PM • P-ush -- APP mode (or VOR/LOC or LNAV or Hdg Sel) • S-peeds -- set/verify Vref is set and displayed for flap setting Engine Failure on Takeoff • “4 Cs” (accomplished when flaps are up at min. maneuvering speed) • C-hange (Level Change) • C-ontinuous (Max Cont) • C-rossfeed (with fuel only in wing tanks) • C-hecklist (NNP then After Takeoff) Single Engine Trim • Trim into good engine is approximately equal to Fuel Flow Single Engine ILS Approach • At 1.5 Dots or later on the Glide Slope -- • Gear Down • Flaps 15 • Reduce Thrust 10% N1 Non-ILS Approach (VNAV is preferred for straight-in approaches) • 3 NM -- Configure (Gear Down/Flaps 15, Bug 15, Landing checklist to flaps) • 2 NM -- or sooner/Set Next Lower Altitude (ensure VNAV if using) • 1 NM -- Flaps 30, Bug 30, complete Landing checklist • 0.2 NM -- V/S As Desired (unless using VNAV) Touch and go/pattern work Missed Approach Note: Assumes intent for complete flap retraction to missed approach holding pattern. • TO/GA (A/P will kick off under single-channel operation) • Set Go-around thrust • Set pitch to Go-around attitude • “Flaps 15” • Positive climb rate - “Gear up” • 400’ AGL - “LNAV” or “HDG SEL” (Note: for Non-Precision approaches your probably already at/above 400’ AGL or very close if going missed from and DA/DDA/MDA) • Retract flaps on speed • 1000’ AGL - Set LVL/CHG or V/S + 1500’ • After Takeoff checklist (Ops Man) Radar Pattern Climb Out From Touch & Go • PF rotates aircraft to 15 degrees nose high • Positive climb rate - “Gear up” • Flight directors - ON (if coming from VFR Pattern OR Recycle) • 400’ AGL- “Bug Up, flaps 5, LNAV or HDG SEL ” • 1000’ AGL - Technique: "V/S, Set 1500 fpm" or "LVL CHG" • Retract flaps on schedule to “Flaps Up” • After Takeoff checklist • Maintain flaps Up for downwind Note: PF re-establishes A/P and manually arms Autothrottles • PM rechecks weather, installs approach and helps tune nav radios (technique) • PF briefs approach, tunes radios and calls for the “Approach check” Precision Approach (use “CRAMPS” check technique) • Arm APP if cleared approach on intercept heading • G/S alive - “Gear down, flaps 15, Bug 15, landing checklist to flaps" • G/S intercept - “Flaps 30/40 (final flap), Landing checklist” slow to VREF + additive Non-precision approach (non/VNAV) • Arm LNAV or use HDG SEL for lateral maneuvering • 3 miles prior - “Gear down, flaps 15, Bug 15, landing checklist to flaps” • 2 miles prior (or earlier) - Set MDA or stepdown altitude in altitude alert window • 1 mile prior - “Flaps 30/40 (final flap), complete Landing checklist” slow to Vref + additive Note: Do not arm speedbrakes or use autobrakes if accomplishing a touch & go. VFR Pattern Climb Out From Touch & Go • PF rotates aircraft to 15 degrees nose high • Positive climb - “Gear up” • Turn off FDs if not already off (technique) • 400’ AGL - “Bug 5, flaps 5” (technique) • 1000’ AGL - PF lowers nose to 10 degrees pitch and reduces thrust (at Bug 5 speed) to approximately 75% N1 (technique) • PF levels off aircraft at 1500’ AGL or pattern altitude and maintains flaps 5 on downwind VFR Pattern • Enter downwind at flaps 5, speed Vref 30 + 40 (Bug 5 speed) • VFR pattern briefing - "30/40 Flap touch and go, Speed is ____" • Approaching abeam touchdown point - “Gear down, flaps 15, bug 15 Landing checklist to flaps” slow to Bug 15 • Before turning or during turn to base - “Flaps 30/40, Bug 30/40 + ___ (additive), complete Landing checklist,” slow to Vref + additive • Descend as required (approximately 600-800 VSI as a guide) Note: Do not arm speedbrakes or use autobrakes if accomplishing a touch & go. Technique for Establishing Automation After Pattern Work Note: Technique used should be pre-briefed. Assumes the "gear up" and "flight director’s - ON " is already called/done. • 400’ AGL "Bug Up, Flaps 5; HDG SEL or LNAV" • 1000’ AGL (or A/R) "Vert Speed + 1500’, Flaps 1" or "Level Change" (Flaps 1 above F5 speed and then flaps on schedule) • PF establishes A/P by selecting CMD and A/Ts -- ARM NG techniques.pdf

-

Anytime, this helps you fly it as its flown in the real world